Controlling Lipid Oxidation: Engineering the Perfect Atmosphere with a Nut Vacuum Packaging Machine

Controlling Lipid Oxidation: Engineering the Perfect Atmosphere with a Nut Vacuum Packaging Machine

Published on: January 21, 2026 | By Jialong Engineering Dept.

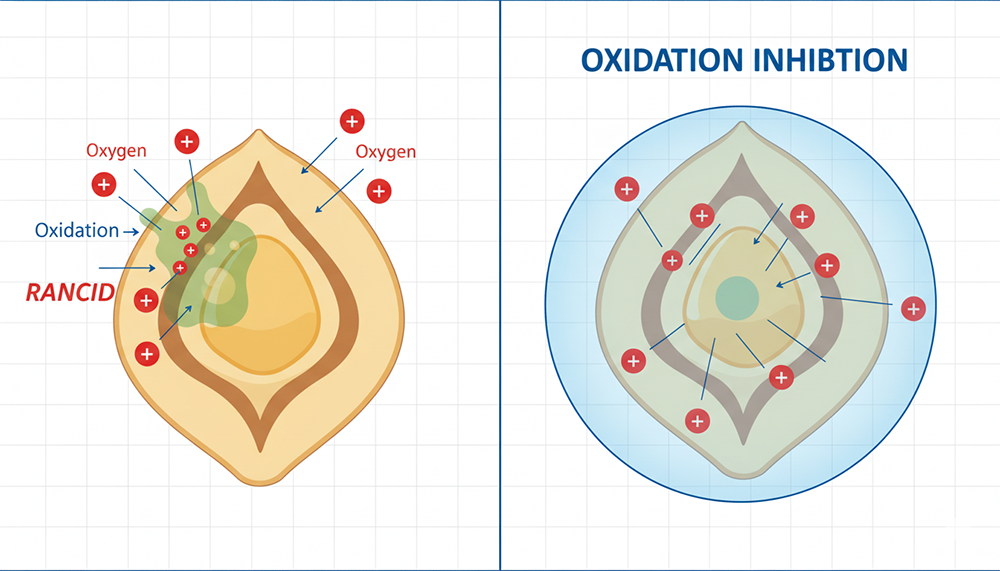

In the food processing industry, nuts represent a high-value challenge. Their rich content of unsaturated fatty acids creates a high risk of lipid oxidation, commonly known as rancidity. The engineering response to this chemical vulnerability is the nut vacuum packaging machine. By reducing the ambient pressure within a sealed environment, this equipment removes the primary catalyst of decay: oxygen. Jialong, as a precision packaging machine manufacturer, engineers every automatic vacuum packing machine to achieve low-millibar residual pressure, creating a stable state for long-term storage.

While vacuum pressure removes air, extreme negative pressure can physically damage brittle kernels like walnuts or cashews. Advanced vacuum sealing technology solves this by introducing Modified Atmosphere Packaging (MAP). An automatic vacuum packing machine can be configured to back-flush inert gases, typically nitrogen, after air evacuation. This nitrogen acts as a cushion, preventing mechanical crushing while maintaining an oxygen-free environment. This capability is a defining feature of a versatile nut vacuum packaging machine versus a standard food vacuum sealer machine. It provides both chemical stability and physical integrity.

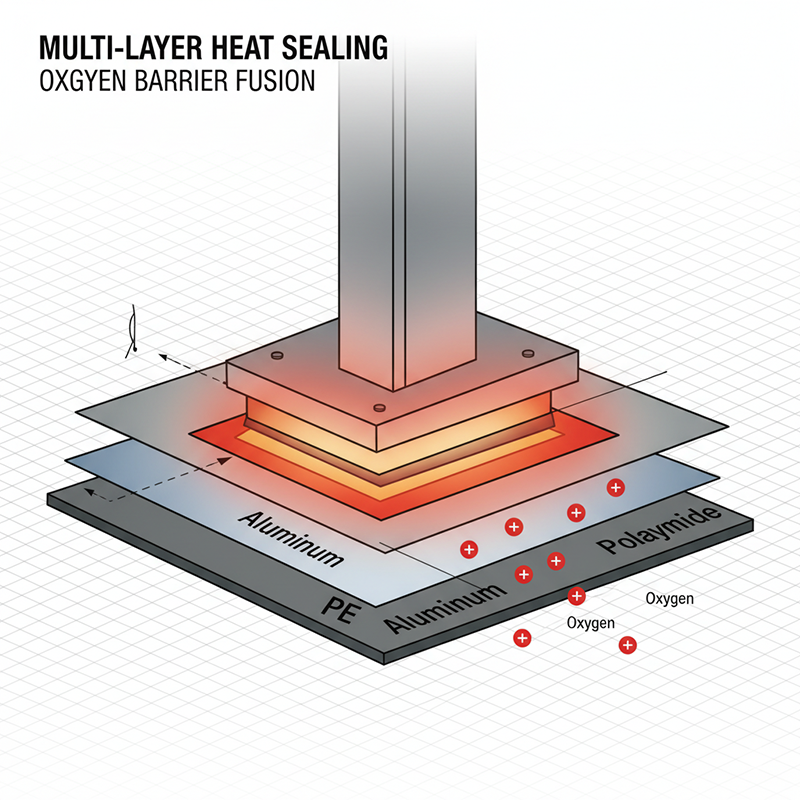

Even the best food vacuum sealer machine relies on the packaging material. Effective preservation requires multi-layer films (Polyamide, PE, Aluminum) with high barrier properties against oxygen and light. As a packaging machine manufacturer, we ensure our sealing bars utilize precise PID temperature control to bond these thick laminates securely. A seal failure in a nut vacuum packaging machine compromises the entire batch. Therefore, seal integrity testing is an integral part of calibrating any automatic vacuum packing machine on the production line.

Shelf Life Validation Parameters

Our clients use acid value and peroxide value testing to validate the performance of our nut vacuum packaging machine. A properly calibrated automatic vacuum packing machine significantly delays the rise of these spoilage indicators. We build vacuum sealing technology you can measure.

View Technical SpecsConclusion: A Systemic Approach to Preservation

The nut vacuum packaging machine is more than an appliance; it is an industrial necessity for quality control. Whether using straight vacuum or nitrogen flush, the key is precise vacuum sealing technology. Jialong, a dedicated packaging machine manufacturer, offers the robust food vacuum sealer machine and automatic vacuum packing machine systems needed to secure your product's lifecycle.

Consult with Our Engineers

We can customize your nut vacuum packaging machine with Nitrogen Flush capabilities. Discuss your specific requirements with us.

Engineer Consultation Visit Jialong Technology