Engineering the Perfect "Rice Brick": Technical Advances in Six-Sided Vacuum Shaping Technology

Engineering the Perfect "Rice Brick": Technical Advances in Six-Sided Vacuum Shaping Technology

Published on: January 5, 2026 | By Jialong Engineering Dept.

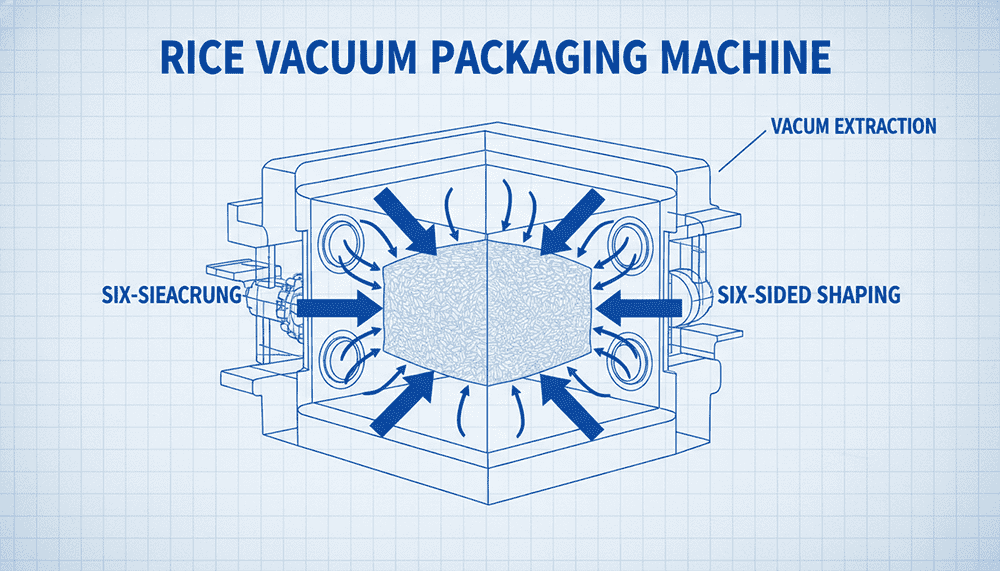

In the high-quality grain distribution sector, the geometric precision of the packaging is as critical as the barrier properties of the film. The six-sided vacuum "rice brick" is not just a shape; it is the result of a sophisticated mechanical process involving vacuum extraction and physical molding. This is achieved through an advanced rice vacuum packaging machine designed to manipulate PA composite films into rigid, rectangular forms. Unlike loose woven bags, a brick shape packaging machine fundamentally alters the physical state of the grain mass, solving deformation issues and setting a new standard for preservation.

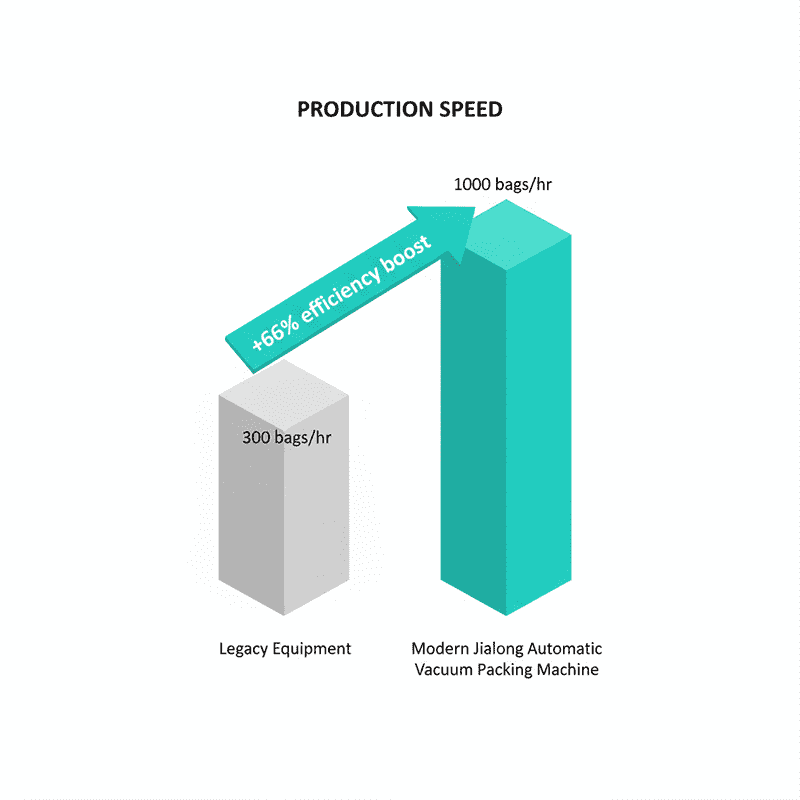

The primary engineering challenge in a rice vacuum packaging machine is reducing residual oxygen. By utilizing high-efficiency vacuum pumps, our systems achieve an environment where oxygen permeability is controlled to less than 5cc/m²·24h. This specific threshold effectively inhibits lipid oxidation and microbial growth, extending shelf life by 3-4 months compared to non-vacuum methods. The brick shape packaging machine integrates this vacuum cycle with mechanical shaping plates. An automatic vacuum packing machine synchronizes these actions to produce consistent 500-1000 bags per hour, ensuring hermetic seal integrity.

To achieve the rigidity of a "rice brick," food packaging equipment must be compatible with high-performance materials like PA (Polyamide) composite films. These films require precise temperature-controlled sealing, a feature standard in Jialong's automatic vacuum packing machine. Compared to earlier models, modern dual-chamber systems increase capacity by 66.7%, handling specifications ranging from 0.25kg to 5kg. As a packaging machine manufacturer, we focus on the stability of these brick shape packaging machine systems to prevent vacuum leakage during high-speed production.

The Next Generation of Intelligent Packaging

Our R&D as a packaging machine manufacturer is pushing towards IoT integration. Our latest rice vacuum packaging machine allows real-time parameter tracking for intelligent quality control. We invite you to explore how this advanced food packaging equipment is redefining industry standards.

View Machine SpecsConclusion: Technical Superiority of the Brick Format

The six-sided rice vacuum packaging machine is more than a trend; it is an engineering solution to logistics and preservation. A brick shape packaging machine delivers quantifiable benefits in density and shelf life. Using a Jialong automatic vacuum packing machine ensures your food packaging equipment meets the demands of modern distribution.

Consult with Our Engineers

We can customize a brick shape packaging machine to your specific density and film requirements. Contact our packaging machine manufacturer team today.

Engineer Consultation Visit Jialong Technology