"Going Global": The Rise Of Fujian Grain Packaging Machinery And Equipment Industry Highland

"Every time I see fully automated packaging machinery from Zhangzhou on production lines in rice processing plants thousands of miles away, I feel a sense of pride and gratification," said Lin Zhaoyu, Deputy Director of the Fujian Provincial Grain and Materials Reserve Bureau.

In Zhangzhou, Fujian, grain packaging machinery is assembled, tested, and then shipped across the country and to numerous regions and countries worldwide. How has Zhangzhou (not a major grain-producing area) managed to nurture a group of companies that hold about 70% of the domestic market share in grain packaging machinery and establish itself as a highland in this specialized manufacturing sector?

Through interviews, reporters found that it is the entrepreneurial spirit of "daring to pioneer and striving for success," cultivated in Fujian, that has empowered Zhangzhou's private grain packaging machinery companies to boldly "go global." They continuously step out of their comfort zones in terms of environment, technology, and market, persistently enhancing competitive advantages, fully leveraging cluster effects, and steadily expanding industrial scale—ultimately shaping this "vibrant" niche industry.

"Going Global": From "Small Machines" to a New Industry of Complete "Big Systems"

Semi-automatic and fully automatic packaging machinery from Zhangzhou is now widely used in industries such as rice processing and feed production, with applications expanding into pet food, chemical granules, and even precious metal particles.

Established in 2000, Zhangzhou Jialong Technology Co., Ltd. is a high-tech enterprise specializing in the R&D, production, and sales of electronic quantitative packaging equipment, automatic weighing and packaging machines, vacuum packaging systems, automated production lines, and industrial robot integration.

Three decades ago, Cai Songhua, Chairman of Jialong Technology, shifted his focus from sugar weighing scales to developing grain quantitative packaging scales and machines. By assembling a skilled technical team with both innovation expertise and hands-on experience—and implementing a technology innovation incentive mechanism—he fostered a culture of creativity, providing strong support for continuous product upgrades.

In 2004, Jialong achieved a milestone by winning a National Torch Program project and successfully launching China’s first six-sided vacuum packaging machine.

"Starting with a small machine like a weighing scale, Jialong has grown over 20 years into a national-level 'Little Giant' enterprise (a specialized and sophisticated SME) with nearly 100 models of automatic packaging machines and complete automated systems," said Guo Xuefeng, the company’s Deputy General Manager.

Like Cai Songhua, who ventured out to found Jialong, many professionals entered the field during that period. At its peak, Zhangzhou was home to nearly 20 grain packaging machinery manufacturers, solidifying its status as an industry hub.

"Going Global": Accelerating the Integration of Automation and Smart Technologies

In March 2024, Fujian's Department of Industry and Information Technology released its list of major breakthrough technological equipment, recognizing Zhangzhou Jialong Technology's "Fully Automatic Six-Sided Secondary Bagging Machine (ZBD-1200)" as a "provincial first-of-its-kind innovation."

To strengthen its technological foundation, Jialong has established long-term industry-academia-research partnerships with universities such as Fuzhou University, Wuhan Polytechnic University, and Fujian University of Technology, jointly developing platforms like Fujian’s "Joint R&D Center for Metering and Packaging Equipment" and the "Collaborative Innovation Platform for High-End Flexible Smart Packaging Systems." To date, the company holds over 400 proprietary patents.

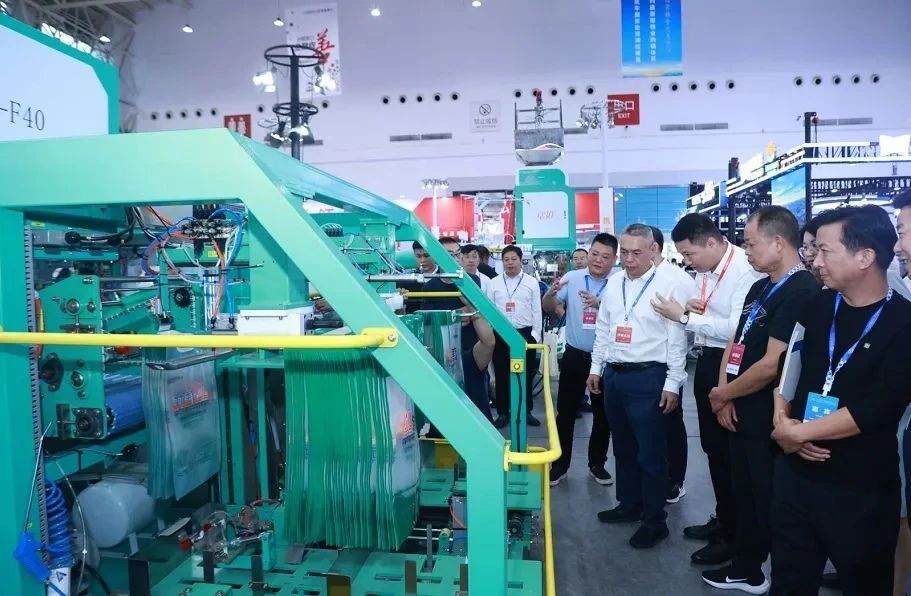

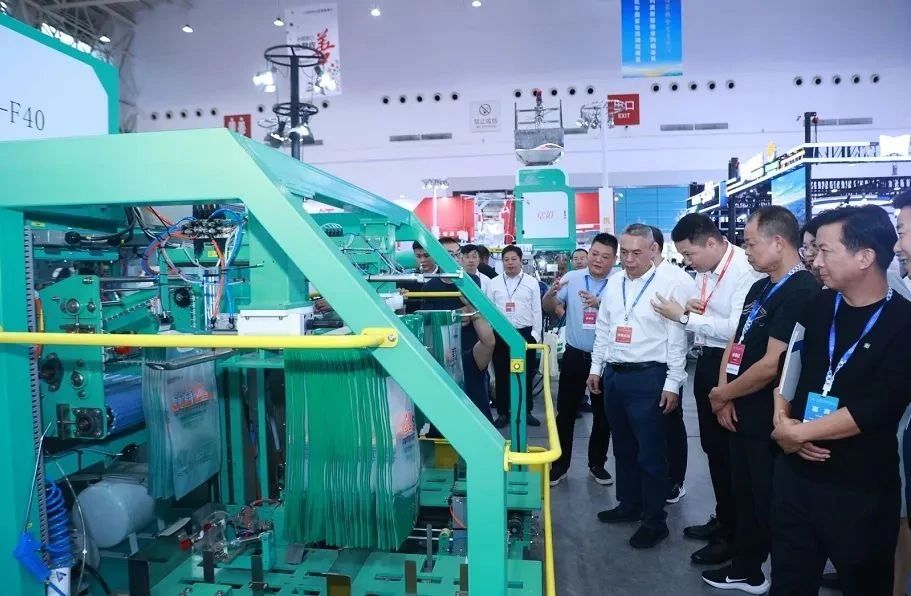

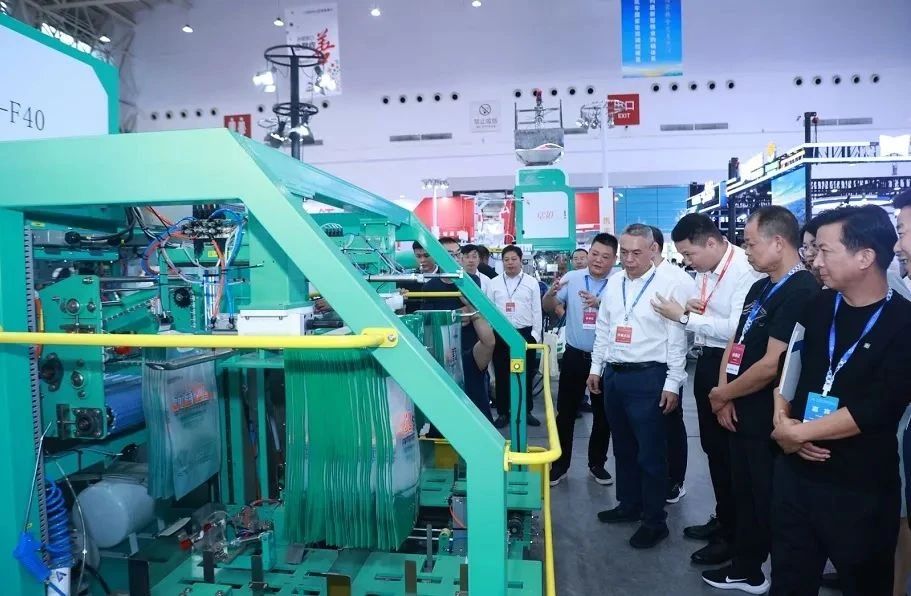

In Jialong’s automated packaging equipment demo hall, Board Secretary You Shuixiang explained how continuous innovation has allowed this next-generation bagging machine to seamlessly integrate with traditional production lines, achieving full automation from primary to secondary packaging.

The company is also pioneering ways to merge automation with smart technologies. "Next, we plan to integrate computer vision and AI large language models to enable automated quality inspection, self-diagnosis for equipment faults, and significantly improve troubleshooting efficiency," said Guo Xuefeng. "We’re also enhancing data collection and analytics in packaging processes to optimize production capacity through data-driven insights."

By embracing cutting-edge tech, Jialong is redefining intelligent packaging—proving that "going global" isn’t just about market expansion, but also about leading the industry’s digital transformation.

"Going Global": Embracing New Opportunities in Packaging Equipment Upgrades

As domestic grain machinery manufacturers grow stronger and enhance production capabilities, Chinese-made equipment is gaining global traction—particularly in Belt and Road Initiative (BRI) partner countries, where grain machinery trade has become a key pillar of cooperation. While consolidating their domestic market presence, Fujian's packaging equipment manufacturers are accelerating their global expansion.

Jialong Technology exemplifies this trend, actively showcasing cutting-edge packaging solutions at international trade fairs to boost brand recognition. Its equipment now serves 50+ countries across Southeast Asia, South Asia, the Americas, and Africa, supported by a robust sales and after-sales network. Exports currently account for 10-15% of annual shipments.

Yet challenges persist: homogeneous export models, excessive competition, and limited brand influence constrain the industry's global potential. To advance, manufacturers must:

Enhance product competitiveness through innovation

Strengthen cross-border collaboration via industry alliances

Transition from equipment exports to technology/equity exports

Prioritize localization—especially in post-sales services

"Southeast Asia's rice-centric markets present massive potential," noted Guo Xuefeng. "As mills upgrade from semi-automatic to smart production lines, we must accelerate overseas service networks to capture this equipment modernization wave."

This ambition aligns with Fujian's private-sector-driven growth strategy. As Provincial Party Secretary Zhou Zuyi emphasized: "We remain committed to nurturing private enterprises—ensuring this vibrant economic 'forest' grows ever more lush and dynamic."

(Source: Grain & Oil Market News, front page, April 29, 2025. Reporter: Zhao Ruihua)