Proven Reliability: Why the DCS-50-A3 is the Cornerstone of Your Granule Packaging Line

Introduction: In High-Paced Production, "Stability" is the Ultimate Competitive Edge

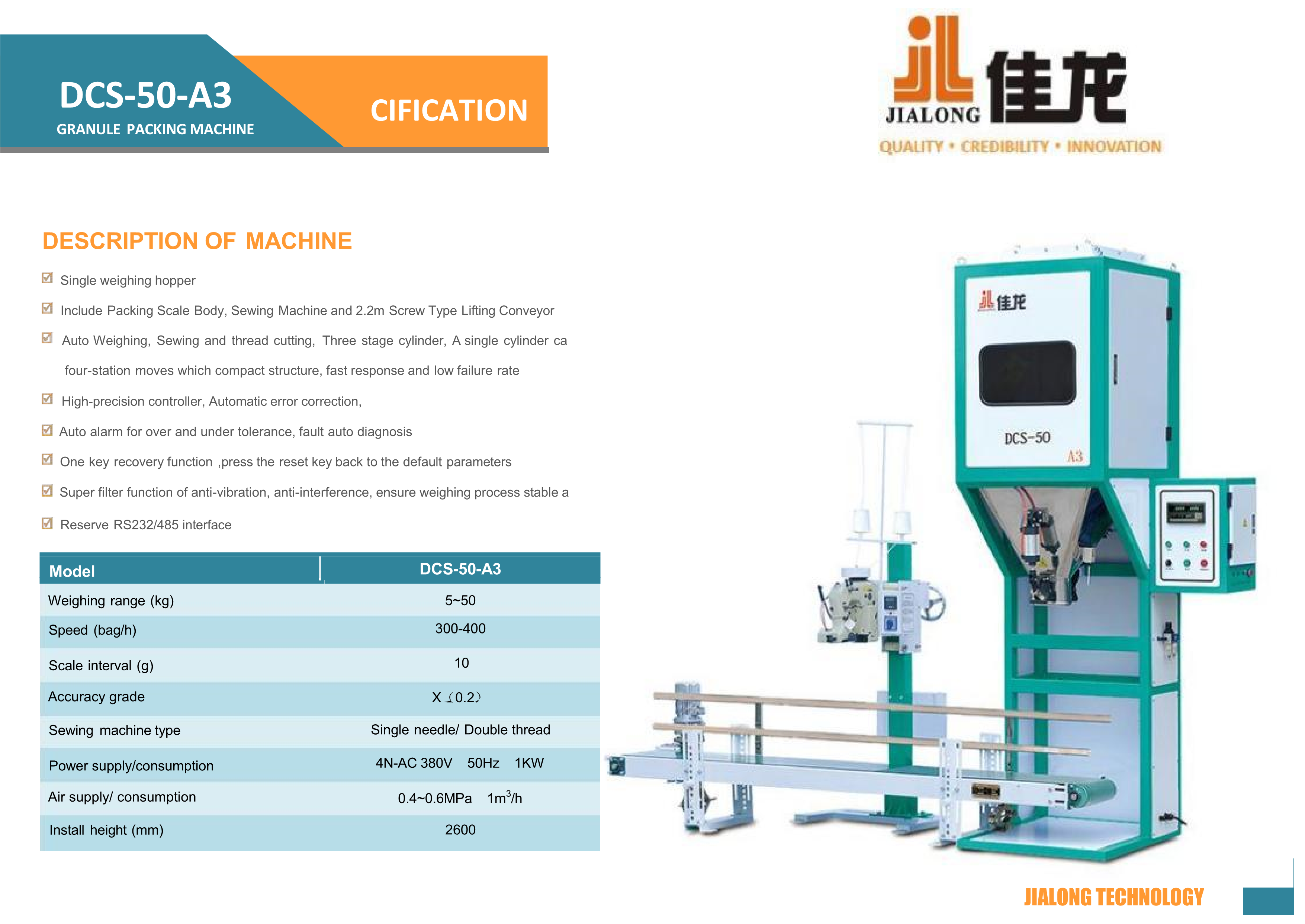

Chapter 1: The Wisdom of Design – The Stability Advantage of the Single Hopper Structure

Simplified Structure, Fewer Failure Points: Fewer mechanical linkage parts translate to a lower potential failure rate and a more straightforward maintenance process. This advantage is particularly prominent on a fertilizer production line that requires 24/7 continuous operation or in a dusty animal feed processing workshop. Built to Last, with Quality in Every Core Component: The machine's durability stems from a stringent selection of materials and components. All parts in contact with materials are made of stainless steel, which effectively resists corrosion when handling mildly corrosive industrial salt or chemical raw materials, significantly extending the machine's service life. Furthermore, key electrical components, such as push buttons from FR/Schneider (France) and a switching power supply from TW/Meanwell (Taiwan), provide a solid electrical foundation for the machine's long-term stable performance.

Chapter 2: A Legacy of Precision – Mature Technology Guarantees Every Bag's Weight

Three-Stage Cylinder Feeding: A "fast, medium, slow" three-stage feeding logic ensures that when bagging large specifications like 50kg sacks of rice or beans, the machine maintains a high feeding speed in the initial phase while achieving precise weight control through the slow feed at the end. The "Anti-Interference" Safeguard: Vibrations and electromagnetic interference in a factory environment are natural enemies to the accuracy of electronic scales. The DCS-50-A3's built-in super filter function effectively shields against these external disturbances. This ensures that whether in a bustling grain warehouse with forklift traffic or a plastic pellet processing plant with large machinery operating nearby, its weighing data remains consistently stable and accurate.

Gentler on Materials: The screw conveyor provides a relatively smooth lifting motion, which is effective in reducing the breakage rate for materials that need to maintain their particle integrity, such as seeds, cat food kibble, or certain fragile chemical granules. Better Dust Control: For materials that easily generate dust, such as wall putty powder or dry mix mortar in the building materials sector, the semi-enclosed nature of the screw conveyor helps to suppress dust dispersion, thereby improving the working environment.