The Critical Role of Vacuum Sealing in Pharmaceutical Packaging: A Technical Analysis

The Critical Role of Vacuum Sealing in Pharmaceutical Packaging: A Technical Analysis

A Jialong Technology Technical Brief | 27/10/2025

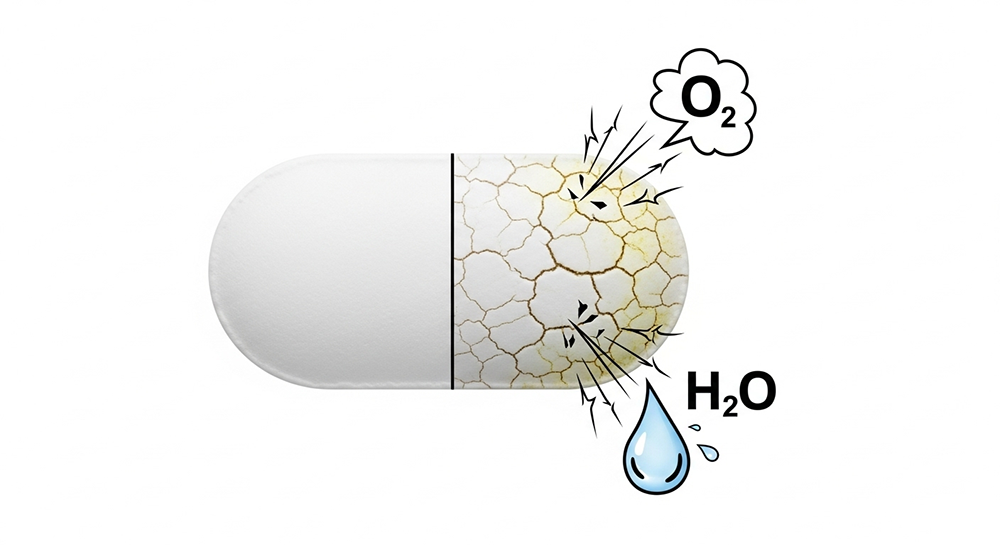

Pharmaceutical packaging transcends mere containment; it is an integral part of ensuring drug stability, efficacy, and safety. The primary objective is to protect the active pharmaceutical ingredients (APIs) from degradation caused by environmental factors. Oxygen and moisture are among the most potent catalysts for such degradation. Consequently, the use of a high-performance vacuum sealer machine has become a technical imperative in this highly regulated industry, representing a critical component in advanced food packaging equipment systems.

The most effective method for oxygen removal in sensitive applications is a chamber vacuum sealer. Unlike simpler nozzle-type machines, a chamber vacuum sealer evacuates air from the entire chamber, ensuring a consistent, low-residual oxygen level that is critical for biologics and other sensitive drugs. The quality of the seal, created by the food packaging sealing machine component, then hermetically isolates the product. This makes the chamber vacuum sealer an essential tool, forming the core of many automatic packaging systems in the industry.

In the pharmaceutical sector, processes must be validated and repeatable. Modern automatic packaging systems that incorporate a vacuum sealer machine offer precisely this. Every parameter—vacuum level, seal time, and temperature—is digitally controlled and logged. The precision of the food packaging sealing machine is a critical parameter for process validation (PQ). This ensures that every package meets the same stringent quality standard, a requirement for any cGMP-compliant production line. Such integrated food packaging equipment systems are key to regulatory approval.

Beyond Preservation: Logistical and Safety Benefits

The robust packaging from a quality vacuum sealer machine also provides superior physical protection, reducing breakage during transport. The tight pack from a chamber vacuum sealer reduces volume, optimizing logistics. These factors contribute to the overall value of advanced food packaging equipment systems.

Explore High-Purity SolutionsConclusion: A Technical Mandate for Modern Pharmaceuticals

The use of a high-quality vacuum sealer machine is a technical necessity in modern drug packaging. For ultimate control, a chamber vacuum sealer is the preferred technology. As a core part of integrated automatic packaging systems, the food packaging sealing machine ensures the final barrier's integrity. High-quality food packaging equipment systems are indispensable for product stability.

Consult Our Technical Specialists

Our engineers can discuss the specific requirements for your sensitive products, and recommend the ideal food packaging sealing machine or a full line from our automatic packaging systems portfolio.

Connect with an Engineer Visit Jialong Technology