The Geometry of Freshness: Engineering the Perfect Rice Vacuum Brick

The Geometry of Freshness: Engineering the Perfect Rice Vacuum Brick

Published on: February 4, 2026 | By Jialong Grain Engineering Dept.

In the world of grain logistics, shape matters as much as chemistry. A loose bag of rice is a logistical nightmare—it shifts, it breaks, and it breathes. A vacuum brick, however, is an engineering triumph. It transforms a flowable granular product into a solid, stackable unit. But achieving this requires more than just sucking out air. It requires precise grain preservation technology.

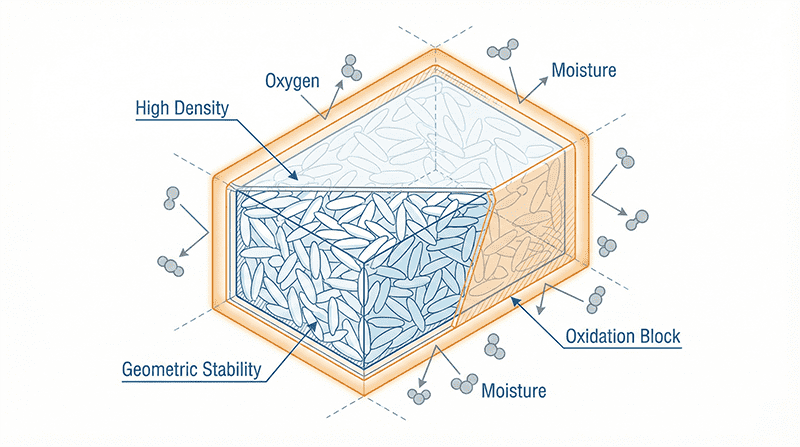

At Jialong, we view the rice vacuum packing machine not just as a packaging tool, but as a preservation reactor. The goal is to achieve two things: total oxidation inhibition and absolute geometric stability. This report deconstructs the science behind why vacuum brick packaging has become the global standard for high-quality rice.

Figure 1: The dual-chamber design ensures continuous vacuum pressure.

The rice weevil (Sitophilus oryzae) is the scourge of the industry. Their eggs are microscopic and often present inside the grain kernel before harvest. Traditional fumigation is losing favor due to chemical residue concerns. The only physical way to prevent rice weevils is oxygen deprivation.

A standard seal is not enough. To effectively prevent rice weevils, the oxygen level within the bag must drop below 1%. This requires a rice vacuum packing machine capable of pulling a vacuum pressure of -0.08MPa or lower. Under these conditions, the biological activity of eggs, larvae, and aerobic mold stops completely. Grain preservation technology is essentially about suffocating the threat before it hatches. Without vacuum brick packaging, you are leaving your inventory vulnerable to infestation during the weeks of ocean transit.

Rice contains lipids (fats), especially in the bran layer of brown rice. When exposed to air, these lipids oxidize, creating stale, rancid "off-flavors." Oxidation inhibition is the key to maintaining premium pricing.

Vacuum brick packaging removes the catalyst (oxygen) from the equation. By utilizing high-barrier nylon/PE films in conjunction with our rice vacuum packing machine, we create a hermetic seal that maintains oxidation inhibition for up to 12 months. This grain preservation technology ensures that the rice cooking in the consumer's pot tastes exactly as the farmer intended.

Figure 2: Without oxidation inhibition, lipid degradation accelerates rapidly.

The Logistics of the Brick Shape

Why the brick shape? It is about density. Vacuum brick packaging compresses the volume of the rice by approximately 20%. This means you can fit 20% more product into a shipping container compared to loose sacks. For high-volume exporters, the rice vacuum packing machine pays for itself in freight savings alone.

Furthermore, the rigidity of the brick prevents internal friction. In loose bags, grains rub against each other, creating broken rice and dust. Vacuum brick packaging locks every kernel in place. This aspect of grain preservation technology protects the physical integrity of the rice (head rice yield). To prevent rice weevils and prevent broken rice simultaneously, the "Secondary Vacuum" mold technology of Jialong is essential.

Conclusion: Engineering for the Future

The transition from loose bags to vacuum brick packaging is scientifically inevitable. It is the only method that combines oxidation inhibition with logistics efficiency. By deploying a Jialong rice vacuum packing machine, you are not just packaging; you are applying advanced grain preservation technology to prevent rice weevils and secure your market position.

Upgrade Your Processing Line

Our engineers can calculate the exact freight savings and shelf life extension for your specific grain variety.

Consult an Engineer Visit Jialong Website