The Oxidative Barrier: Engineering the Future of Industrial Flour Preservation

The Oxidative Barrier: Engineering the Future of Industrial Flour Preservation

Published on: February 11, 2026 | By Jialong Powder Engineering Dept.

In the milling industry, a silent crisis is occurring. High-quality flour, rich in wheat germ oil and nutrients, is degrading before it even reaches the baker's oven. The culprit is oxygen. Traditional woven or paper bags allow air to flow freely, accelerating lipid oxidation. To solve this, the sector is pivoting toward industrial flour packing solutions that utilize vacuum technology. However, vacuuming powder is an engineering challenge. It requires specialized powder packaging technology to handle the dust while ensuring a perfect seal. The deployment of a robust flour vacuum packing machine is no longer a luxury; it is a necessity to extend flour shelf life and guarantee quality.

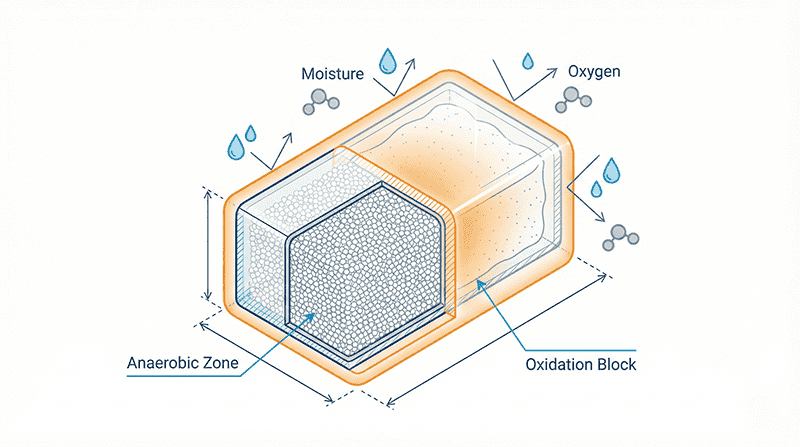

Figure 1: Vacuum bricks create a dense, oxygen-free environment.

Why does flour smell "old"? It is due to the oxidation of unsaturated fatty acids within the wheat germ. This chemical reaction produces aldehydes and ketones, which create off-flavors. To prevent flour rancidity effectively, one must remove the catalyst: oxygen.

A Jialong flour vacuum packing machine evacuates the bag to a pressure of -0.08MPa. This creates an anaerobic environment where oxidation virtually stops. Standard industrial flour packing methods cannot achieve this. By integrating advanced powder packaging technology, we can extend flour shelf life from 6 months to over 12 months. This extended window is crucial for exporters who need to prevent flour rancidity during long ocean transits. Without a flour vacuum packing machine, you are fighting a losing battle against chemistry.

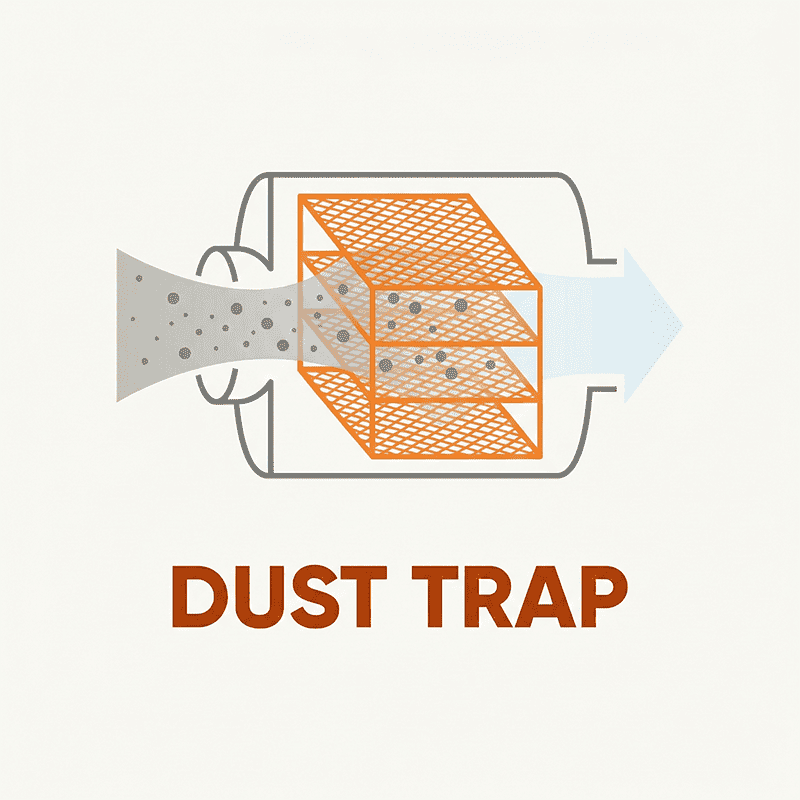

Vacuuming grain is easy; vacuuming flour is hard. The fine particles can clog pumps and destroy seals. This is why specialized powder packaging technology is required. A generic machine will fail in weeks. The Jialong flour vacuum packing machine features a proprietary multi-stage filtration system designed specifically for industrial flour packing.

This system isolates the flour dust before it reaches the vacuum pump. By keeping the mechanics clean, we ensure consistent performance. This reliability is essential if you want to extend flour shelf life across high-volume production runs. Standard equipment simply cannot handle the rigors of industrial flour packing. To prevent flour rancidity consistently, the machine must be engineered for powder.

Figure 2: Advanced filtration is the heart of reliable powder packaging.

Logistics and Density: The Hidden Value

Industrial flour packing is also a logistics game. Aerated flour takes up massive space. Our flour vacuum packing machine compresses the powder into a dense brick, reducing volume by 30%. This density not only helps extend flour shelf life by minimizing air gaps but also slashes shipping costs.

Furthermore, the rigid brick prevents pest infestation. Weevils cannot survive in a vacuum. This is a key aspect of powder packaging technology—it provides biological protection. To prevent flour rancidity and insect damage simultaneously, the flour vacuum packing machine is the only viable solution. Upgrading your industrial flour packing line is an investment in both quality and efficiency.

Conclusion: The Scientific Standard

The future of the milling industry relies on advanced powder packaging technology. By adopting the Jialong flour vacuum packing machine, you do more than just pack; you prevent flour rancidity, you extend flour shelf life, and you elevate your industrial flour packing to a global standard.

Upgrade Your Processing Line

Our engineers can demonstrate the dust-proof capabilities of our machines.

Consult an Engineer Visit Jialong Website