Zhangzhou Jialong Tech’s Fully Automated Packaging Systems Double Rice Packing Efficiency, 450+ Patents Cement Industry Leadership

As a National-Level “Little Giant” Enterprise (specialized, sophisticated, innovative) and Fujian Provincial Manufacturing Champion, Jialong leads the rice packaging sector through relentless R&D. Since 2025, it has secured patents for breakthroughs including the Heat-Sealing Bag-Organizing Mechanism, Push-Pack Bagging System, and Single-Sensor Metering Unit, bringing total patents to 450+.

01 Tech Revolution: From Human-Dependent to Fully Automated

While dual-layer rice packaging (inner vacuum brick + outer branded bag) ensures hygiene and aesthetics, traditional production relied on manual secondary bagging—slow and inconsistent. Jialong’s Six-Side Double-Bagging Machine delivers disruptive change through three innovations:

Seamless legacy line integration: Fully automates primary-to-secondary packaging without retrofitting;

Efficiency doubled: Output surges to 1,000 bags/hour with 90% less labor;

Precision boost: Patented Single-Sensor Metering cuts measurement error below 0.5% with side-mounted sensors eliminating corner deviations.

Certified as Fujian’s First Major Technological Equipment, this system is redefining grain packaging standards.

02 Patent Fortress: 450+ Technologies Form Unbreachable "Moat"

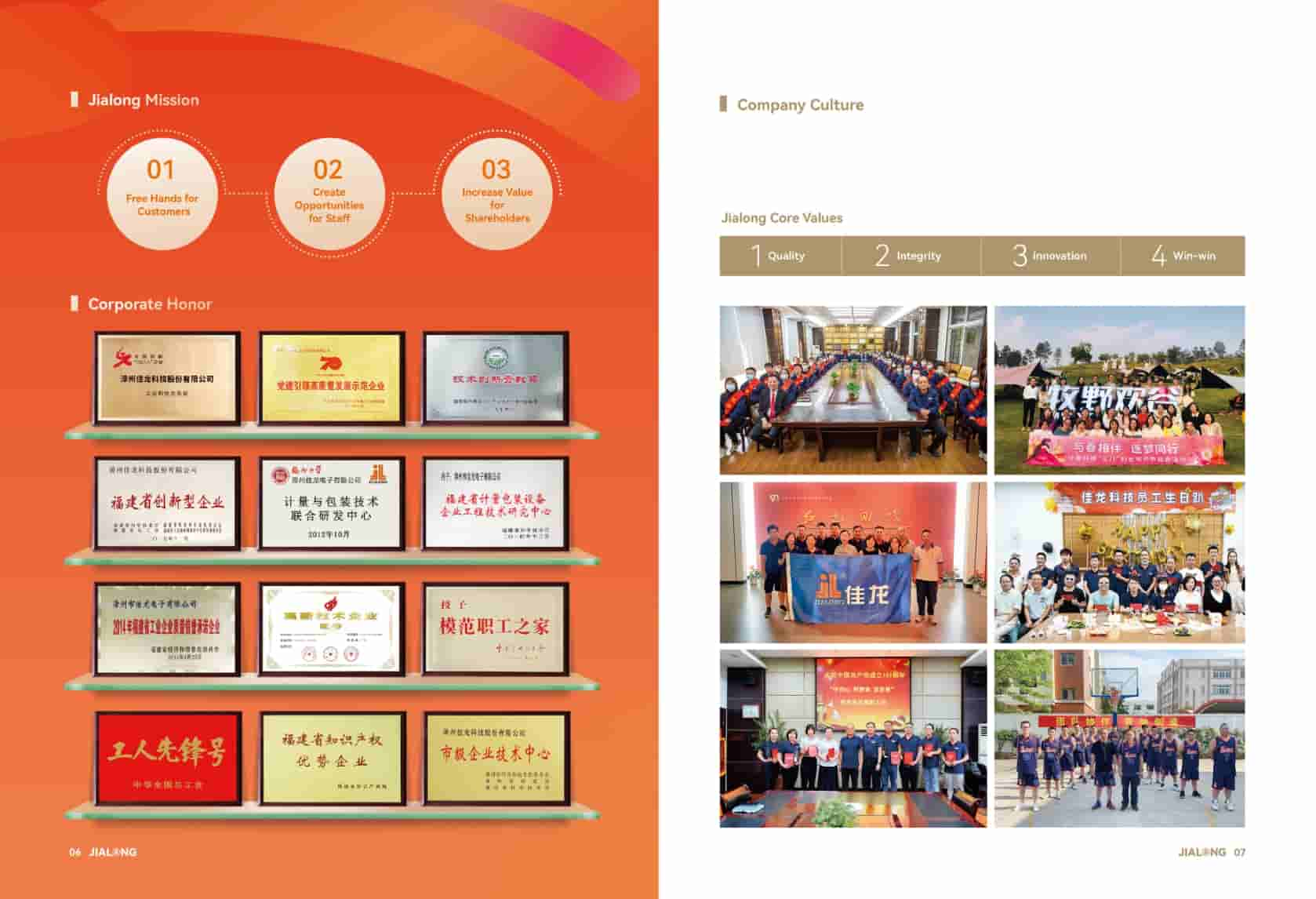

Since its 2000 founding, Jialong has evolved from a single-equipment maker to a full-chain solution provider with nearly 100 automated packaging models. Its technical edge stems from two pillars:

R&D ecosystem: Hosts Fujian’s sole Weighing & Packaging Technology Research Center and partners with Fuzhou University/Wuhan Polytechnic University via the High-End Flexible Smart Packaging Equipment Platform;

Patent clusters: 2025 additions include:

▶︎ Heat-Sealing Mechanism (enhances bag-mouth deformation control);

▶︎ Push-Pack System (30% higher component synergy efficiency);

▶︎ Single-Sensor Metering (20% smaller footprint, higher accuracy).

With 454 patents spanning metering, filling, and vacuum shaping, Jialong dominates end-to-end packaging IP

03 Global Strategy: Capturing Southeast Asia’s Automation Upgrade Wave

While holding 70% of China’s market, Jialong accelerates global penetration:

Global reach: Exports to 50+ countries across Southeast Asia, South America, and Africa, comprising 10%-15% of total shipments;

Strategic focus: Southeast Asia is pivotal. Deputy GM Guo Xuefeng notes the region’s rice processing lines are undergoing a “semi-automatic → fully automated → intelligent” upgrade wave, driving demand for cost-effective solutions;

Localized service: International support networks and exhibition participation amplify brand influence.

“Seeing our systems in overseas mills—even miles from Fujian—fills us with pride,” remarks Lin Zhaoyu, Deputy Director of Fujian’s Grain Reserve Bureau.

04 Future Roadmap: AI-Driven Intelligence Reshapes Grain Packaging

Jialong’s next-gen technology blueprint targets three frontiers:

AI integration: Embedding visual recognition and large-language models for defect autodetection and failure prediction;

Data empowerment: Real-time parameter optimization via production data analytics to unlock latent capacity;

Flexible manufacturing: Next-gen 3D vacuum packers enable “second-scale mold switching”, eliminating hours of downtime.

Epilogue: From Fujian’s “Little Giant” to Global Grain Tech Pioneer

In 25 years, Jialong has grown from a single scale maker to an industry benchmark with 450+ patents. Its automated systems are rewriting global packaging logic—1,000 perfectly packed rice bags/hour is now routine in Southeast Asian plants; every 0.1% measurement error avoided in American silos reduces waste. As AI vision and data-driven intelligence penetrate production lines, this NEEQ-listed firm (Code: 832394) aims not just for “China’s best” but for making “Made in Zhangzhou” synonymous with grain packaging excellence.