Mitigating the "Hard-to-Cook" Defect: The Engineering Logic of Vacuum-Packed

Mitigating the "Hard-to-Cook" Defect: The Engineering Logic of Vacuum-Packed Legumes

Published on: February 2, 2026 | By Jialong Food Science Lab

Legumes are notoriously difficult to store. The greatest challenge facing the industrial bean packaging sector is the "Hard-to-Cook" (HTC) defect. When beans are stored in loose sacks, they undergo physiological changes that make the cell walls tough. The only scalable way to halt this degradation is by adopting a specialized vacuum packing machine for beans. This equipment is the cornerstone of modern legume preservation technology. By creating a controlled environment, we can effectively prevent hard-to-cook defect formation and ensure oxidation inhibition in pulses.

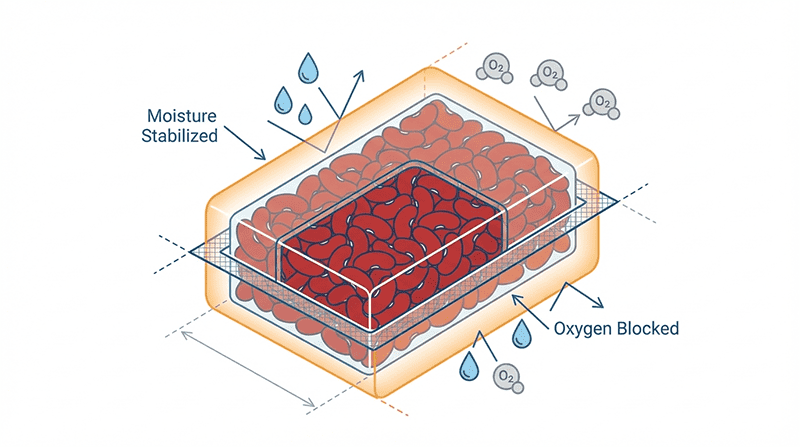

Figure 1: Vacuum bricks stabilize the moisture content of the bean.

To understand why we need advanced legume preservation technology, we must look at the cell wall. In high humidity, phytase enzymes break down, leading to lignification. This turns the bean into wood. This process is accelerated by oxygen, making oxidation inhibition in pulses a critical priority.

By deploying a Jialong vacuum packing machine for beans, processors reduce the oxygen level to below 1%. This reduction is the primary mechanism to prevent hard-to-cook defect. Furthermore, proper industrial bean packaging prevents moisture fluctuation. By stabilizing the bean's internal moisture with our legume preservation technology, we ensure the product remains tender. Without a reliable vacuum packing machine for beans, you cannot achieve the necessary oxidation inhibition in pulses to stop aging.

Red beans darken and chickpeas turn grey due to uncontrolled air exposure. Effective oxidation inhibition in pulses requires a hermetic seal that only a vacuum packing machine for beans can provide. This is a vital aspect of modern industrial bean packaging.

Our legume preservation technology uses high-pressure molds to create dense bricks. This minimizes interstitial air. By maximizing oxidation inhibition in pulses, we protect heat-sensitive vitamins. This method is proven to prevent hard-to-cook defect symptoms like stone cells. Consumers demand fresh-looking beans, and industrial bean packaging must evolve to meet this. Using a vacuum packing machine for beans is the only way to deliver consistency.

Figure 2: Without oxidation inhibition, beans darken and harden rapidly.

The Logistics of Density in Industrial Bean Packaging

Loose beans are inefficient. A vacuum packing machine for beans transforms loose pulses into rigid bricks. This optimizes industrial bean packaging for logistics. More importantly, it helps prevent hard-to-cook defect by stopping physical respiration.

Jialong's legume preservation technology is the bridge between the farm and the kitchen. We help you prevent hard-to-cook defect complaints from end-users. By integrating oxidation inhibition in pulses into your line, you secure your brand reputation. Investing in a vacuum packing machine for beans is investing in quality. The future of industrial bean packaging is undoubtedly vacuum-based.

Conclusion: Engineering Better Food

The HTC defect is solvable. The Jialong vacuum packing machine for beans is the tool that makes this possible. By mastering oxidation inhibition in pulses and adopting advanced legume preservation technology, you can prevent hard-to-cook defect entirely. This is the new standard for industrial bean packaging.

Upgrade Your Processing Line

Our engineers can demonstrate how our vacuum packing machine for beans works on your specific variety.

Consult an Engineer Visit Jialong Website