Balancing Sustainability and Stability: A Technical Comparison of Vacuum Packaging vs. Standard Degradable Films

Balancing Sustainability and Stability: A Technical Comparison of Vacuum Packaging vs. Standard Degradable Films

Published on: December 17, 2025 | By Jialong Engineering Dept.

The global push for environmental responsibility is reshaping food packaging equipment standards. However, a purely material-based switch to degradable options (like PLA or Corn Starch) often introduces technical risks regarding shelf life. For hygroscopic products like grains, coffee, or cat litter, the primary engineering directive is isolation. This report contrasts the efficacy of vacuum sealing technology using high-barrier film against loose packing in degradable materials. As a packaging machine manufacturer, we analyze the data to determine the optimal solution for product stability.

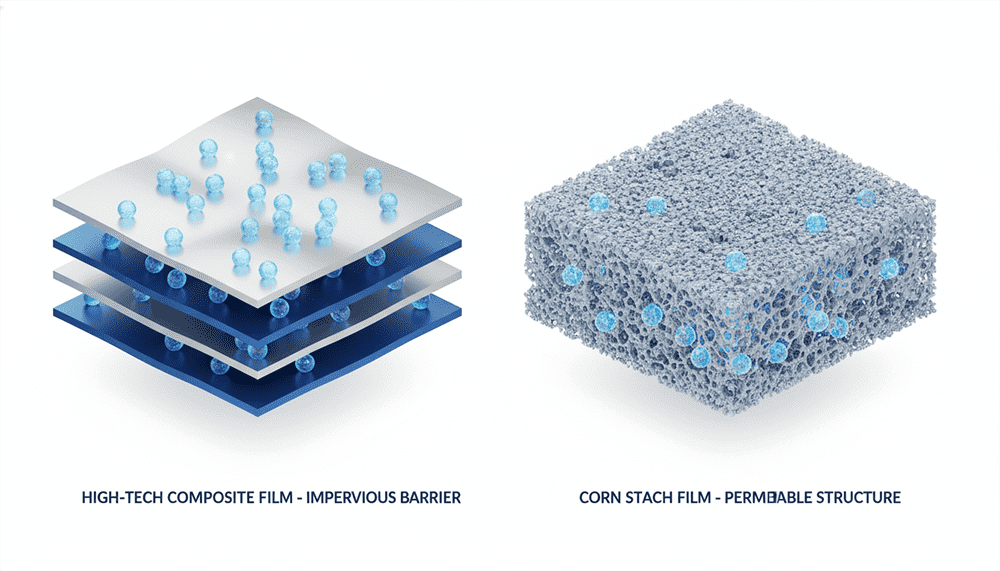

The most significant differentiator is the Water Vapor Transmission Rate (WVTR). A vacuum packaging machine utilizes high-barrier film (typically PA/PE composites) to achieve a near-zero WVTR. This prevents clumping in moisture-sensitive goods. In contrast, standard degradable films have inherent porosity, leading to moisture absorption rates of 8-12%. Engineering data suggests a product clumping rate of 10-15% over time with loose degradable packaging. Vacuum sealing technology eliminates interstitial air, removing the medium for initial moisture exchange, making the vacuum packaging machine critical for long-term storage stability.

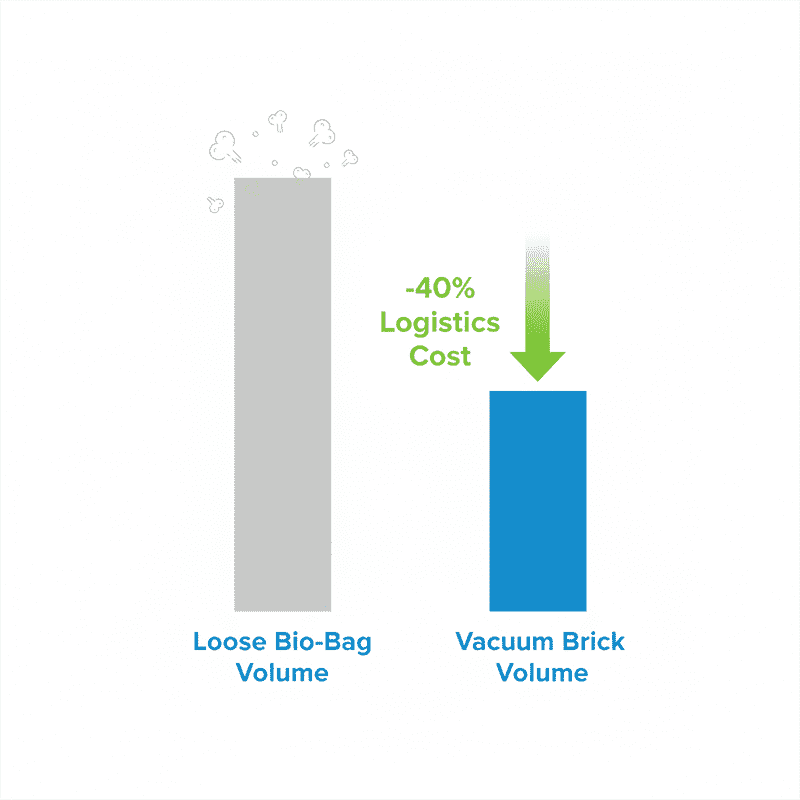

From a logistics engineering perspective, food packaging equipment must optimize volume. A vacuum packaging machine compresses the product, reducing volume by 30-40%. This density allows for 25-35% lower logistics costs due to higher pallet loads. Degradable films, lacking the tensile strength for high-vacuum compression, result in bulky packages. As a packaging machine manufacturer, we calculate that the ROI from logistics savings often offsets the film cost. Effective vacuum sealing technology using high-barrier film transforms logistics from a cost center to an efficiency driver.

The Intersection of Eco-Trends and Performance

The future lies in food packaging equipment that can run eco-friendly variants of high-barrier film. We are engineering our next-generation vacuum packaging machine to be compatible with recyclable high-barrier laminates, ensuring you don't have to choose between the planet and product safety. A responsible packaging machine manufacturer provides solutions that are sustainable and functional.

View Machine SpecsConclusion: Technical Superiority for High-Value Goods

For commodities where freshness determines value, the vacuum packaging machine employing high-barrier film remains the scientifically superior choice. While degradable films have niche applications, vacuum sealing technology offers unmatched protection against moisture and odor transfer. As a packaging machine manufacturer, we recommend food packaging equipment that prioritizes product integrity first, which ultimately reduces waste—the most impactful sustainability metric of all.

Consult Our Material Engineers

We can test your specific high-barrier film on our vacuum packaging machine or help you select the right food packaging equipment configuration. Contact the packaging machine manufacturer that understands material science.

Chat with an Engineer Visit Jialong Technology