- Jialong

- China

- 15 working days

- 50 sets per month

- Packaging Range: 5–25 kg

- Packaging Speed: 900–1400 bags/h

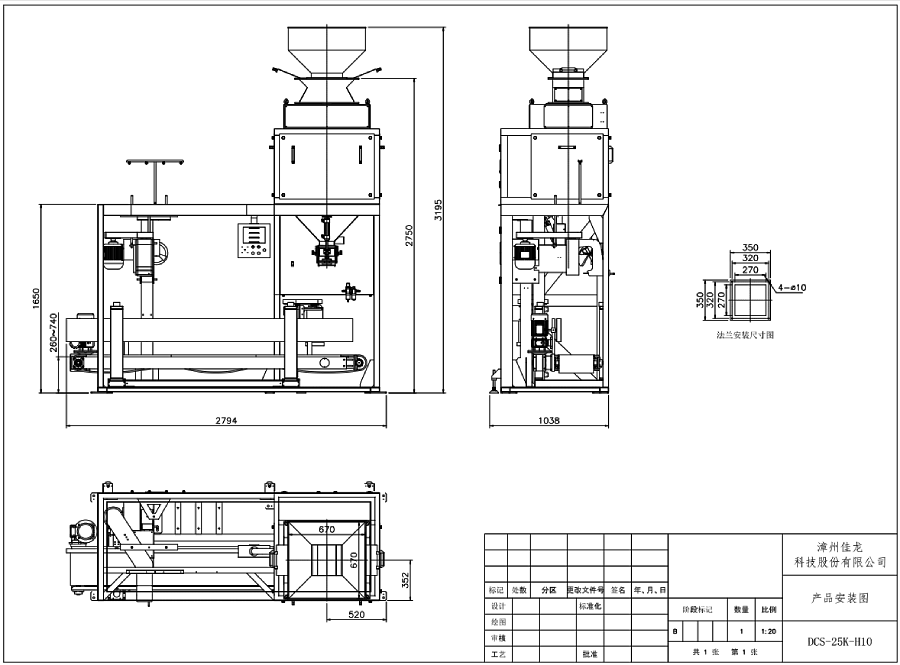

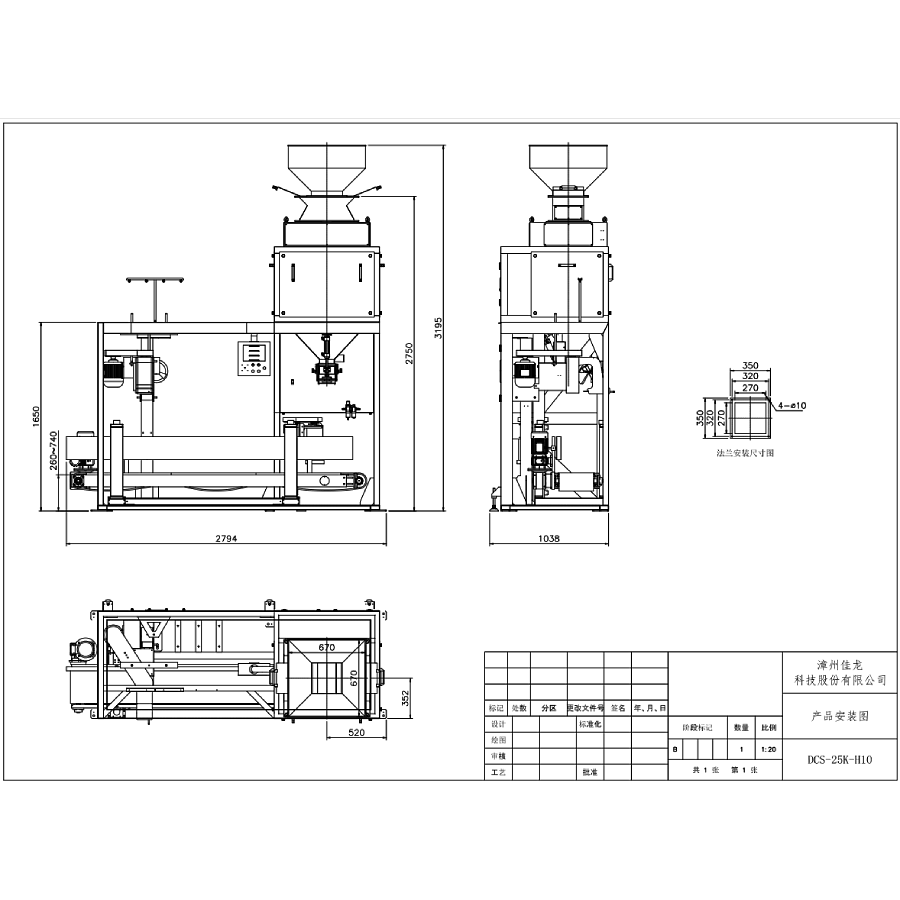

- Packaging Model: DCS-25K-H10

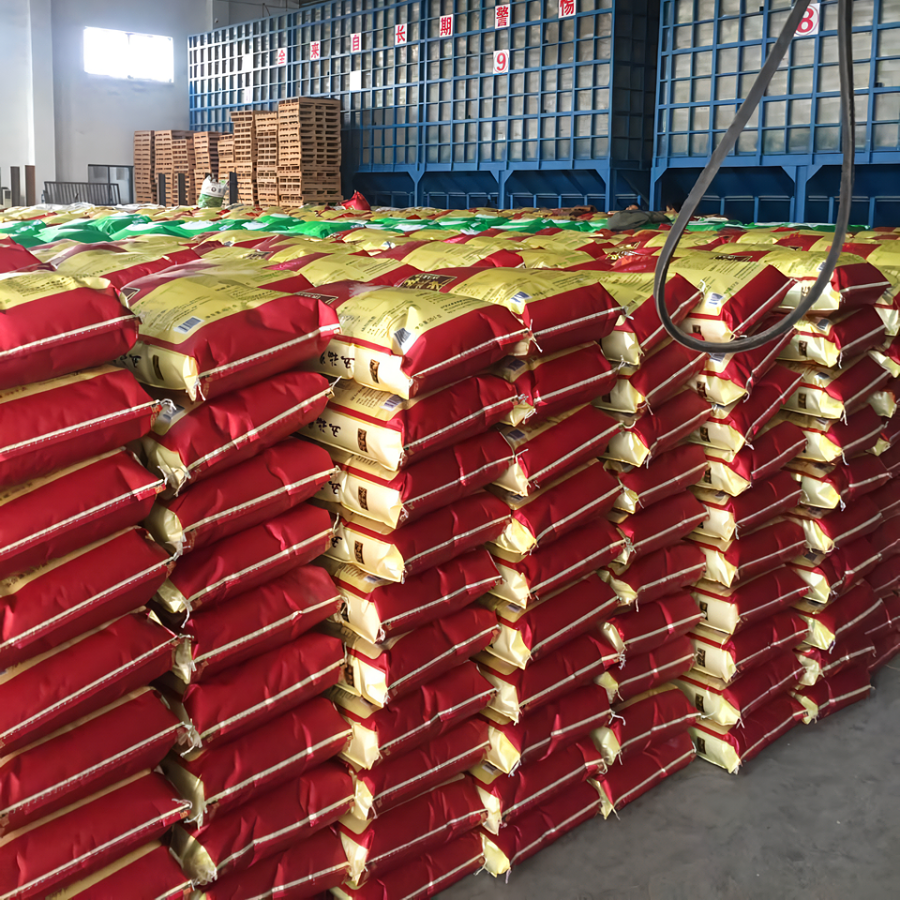

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet,

Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour,

Fertilizer, Powder Wood Pellet, Barley, Oats, Maize, Rye,

Safflower, Sunflower,Rapeseed, Linseed, Sorghum, Lupins, etc.

DCS-25K-H10

High-Speed Rice Packing Machine 1400 Bags Per Hour

Scope of application:

Quantitative packaging of granular materials in grain, sugar, food industries.

Technical Parameters:

Model specifications | DCS-25K-H10 |

Packing range (kg) | 5~25 |

Packing speed (bag / h) | 900~1400 |

Index value (g) | 2 |

level of accuracy | X(0.5) |

Power supply, power consumption | 4N-AC 380V 50Hz 1.1KW |

Air source, gas consumption | 0.5~0.6MPa 13m3/h |

Dimensions (L × W × H mm) | 2800×1050×3200(high with small silo) |

Main configuration:

No. | Name | Main configuration |

1 | Weighing control instrument | United States / Mettler-Toledo |

2 | touch screen | Japan / Omron |

3 | Switching power supply | Japan / Omron |

4 | Buttons, knobs | Japan / Schneider |

5 | Load cell | United States / Mettler-Toledo |

6 | Limit switch | Japan / Omron |

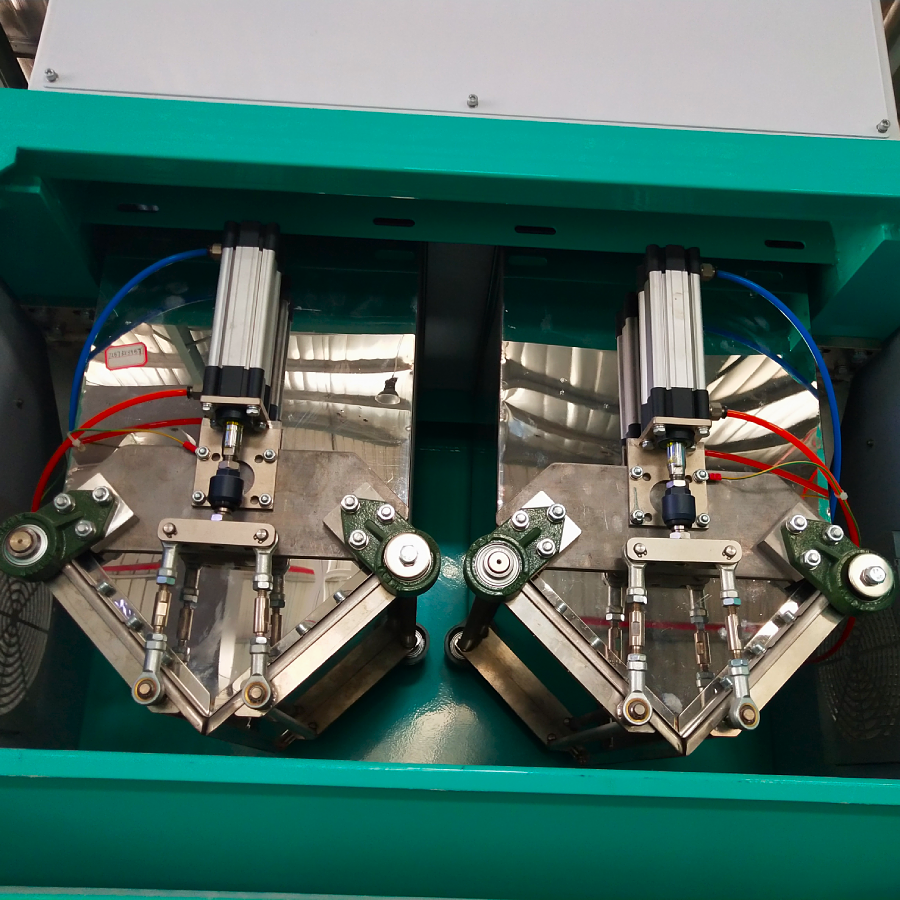

7 | Pneumatic components (filters, solenoid valves) | Taiwan / Airtec |

8 | cylinder | Taiwan / Airtec |

9 | Motor | Ningbo / Sanjing |

10 | Photoelectric switch | Japan / Omron |

Features

● Weighing and conveyor in one body make stable and reliable, no residue design.

● Large size touch screen is displayed and operated in a centralized manner, which is simple and convenient.

● One-key switch of packaging specifications, memory belt automatic lifting.

● Double feeding and double high-speed measuring mechanism, high-speed packing, greatly increasing output.

● Optional to add folding machine, the machine head can be moved laterally, it is easy to operate when it is equipped with or without the folding machine mechanism, it can cut the thread automatically, and automatically stitching machine oil feeding.

● Automatic error correction, over- and under-error alarms, and faults originate from diagnosis and other functions.

● RS232 / 485 serial port is reserved for data communication with the peripheral management system.

Weighing Packing Machine; Quantitative packing scale; bagging system

Picture for reference:

Size: