Automatic Packing Line

-

Hot

5kg 10kg 15kg 20kg 25kg Rice Packing Machine Line Granulate Filling Packaging Sew Machine

5-25kg PP Woven Bag Rice Packing Machine & Packaging Solution Line

- Product Model: ZDB-900-Q30

- Packing Range: 5-25kg

- Packing Speed: 550-900 bags/h

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc.PP Woven Bag Rice Packing Machine Rice Filling Packing Machine 5kg 10kg 15kg 20kg 25kg Rice Packing MachineSend Email Details -

Hot

25kg-50kg Rice Packing Line Solution Bagging And Packing Machine Factory China

25kg–50kg PP Woven Bag Rice Packing Machine & Packaging Solution Line

Send Email Details

- Product Model: ZDB-600-Q9

- Packing Range: 25-50kg

- Packing Speed: 500-600 bags/h

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc. -

Hot

5kg-25kg PP Woven Bag Rice Packing Line Grain Packaging Machine Factory

5-25kg PP Woven Bag Rice Packing Machine & Packaging Solution Line

Send Email Details

- Product Model: ZDB-900-Q8

- Packing Range: 5-25kg

- Packing Speed: 550-900 bags/h

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc. -

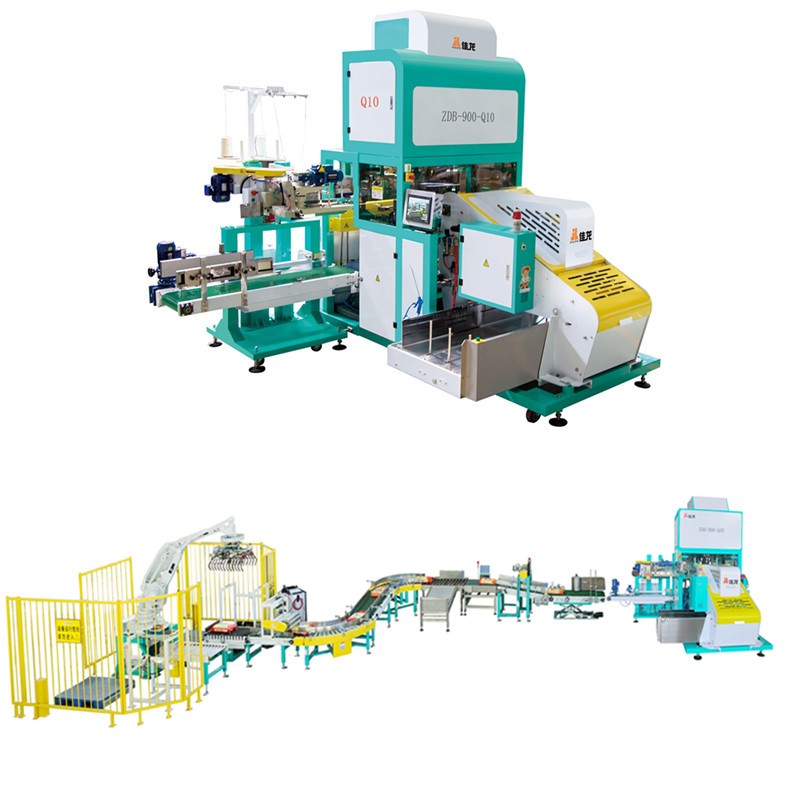

Rice Packing Line Solution Bagging And Palletizing

5-25kg PP Woven Bag Rice Packing Machine & Packaging Solution Line

Send Email Details

- Product Model: ZDB-900-Q10

- Packing Range: 5-25kg

- Packing Speed: 550-900 bags/h

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc. -

Rice Vacuum Packing Line With Robot Palletizer

Rice Vacuum Packing Line With Robot Palletizer

Send Email Details

- Product Model: PZB-900-F8/10

- Packing Range: 2-5/5-10 kg

- Packing Speed: Regular (700~900 bags/h) Vacuum (600~800 bags/h)

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc. -

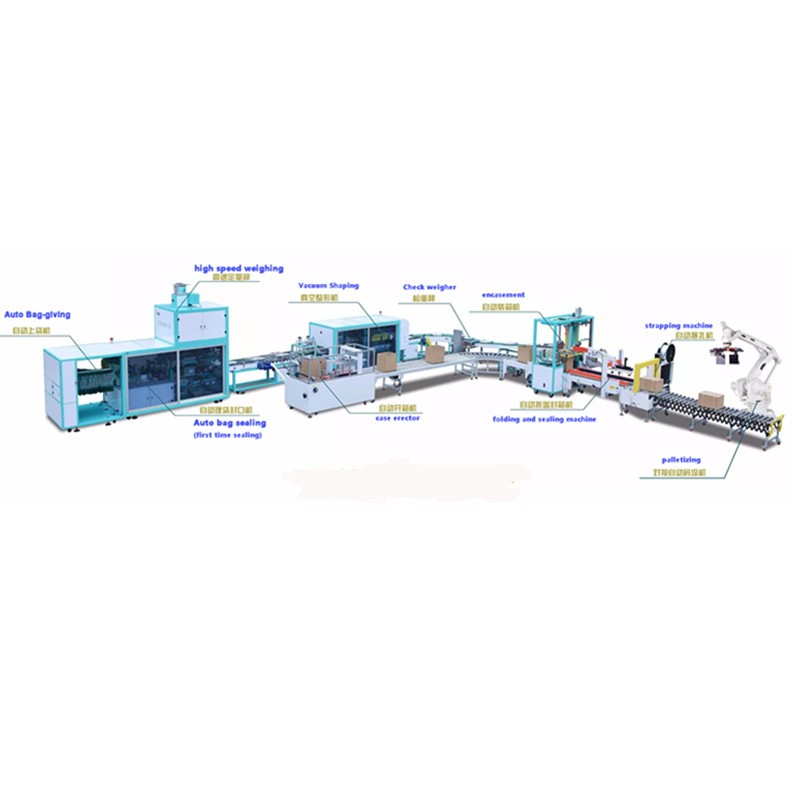

Secondary Packing Line

Packing forms such as automatic feeding, box opening, boxing, batch No. printing, glue spreading, box sealing, etc. are adopted. Featured by compact and reasonable structure, simple operation, and adjustment.

Send Email Details

Servo/step motor, touch screen, PLC control system, and man-machine interface display make operation more clear and convenient. With a high automation degree, the machine is more user-friendly.

The automatic material arranging and conveying mechanism is adopted to facilitate linked production with an automatic production line, which can greatly reduce labor costs.

The photoelectric eye automatic detection tracking system is adopted. No boxing is made if the bag is empty, so as to save packing materials to the utmost extent.

With a wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

Change of specifications does not need a change of molds but can be realized through adjustment.

Automatic stopping is available when the material boxing is not in place, and the main driving motor overload protection device is used so that the machine is safer and more reliable.

According to customer requirements, the upturning type safety protective cover is adopted, which is featured by simple operation and beautiful appearance. -

VFFS Packing Line

The rotary sealing ffs packing machine is suitable for granule material, such as melon seeds, nuts, candy, raisins, Chinese wolfberry, red dates, potato chips, cookies and other solid material automatic packing.

Send Email Details