Beyond the Barrier Material: Why High-Barrier Aluminum Foil Still Needs a Vacuum Packaging Machine

Beyond the Barrier Material: Why High-Barrier Aluminum Foil Still Needs a Vacuum Packaging Machine

Published on: December 31, 2025 | By Jialong Engineering Dept.

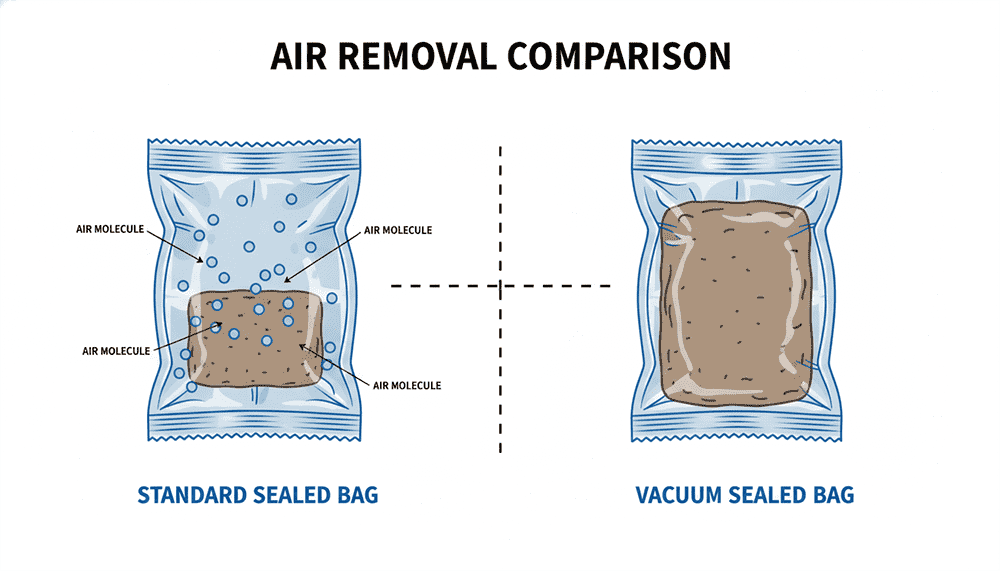

In the pursuit of product stability, many manufacturers rely on high-barrier aluminum foil composite bags. While this material is excellent at blocking external moisture entry, relying on the bag material alone ignores a critical internal variable: residual air. A simple seal leaves atmospheric air trapped inside. This technical report contrasts non-vacuum aluminum foil packaging with the superior results achieved by a vacuum packaging machine. The data shows that vacuum sealing technology is the necessary counterpart to high-grade films.

Using high-barrier aluminum foil without vacuum results in a "puffy" pack containing trapped humidity. Over time, this micro-environment causes a clumping rate of approximately 5% in hygroscopic powders. A vacuum packaging machine, however, mechanically removes this interstitial air before sealing. This active evacuation via vacuum sealing technology reduces clumping risk to near zero. While the material stops new moisture from entering, only the vacuum packaging machine removes the moisture that is already there. For a packaging machine manufacturer, minimizing this 5% variance is the key to engineering quality automatic packaging systems.

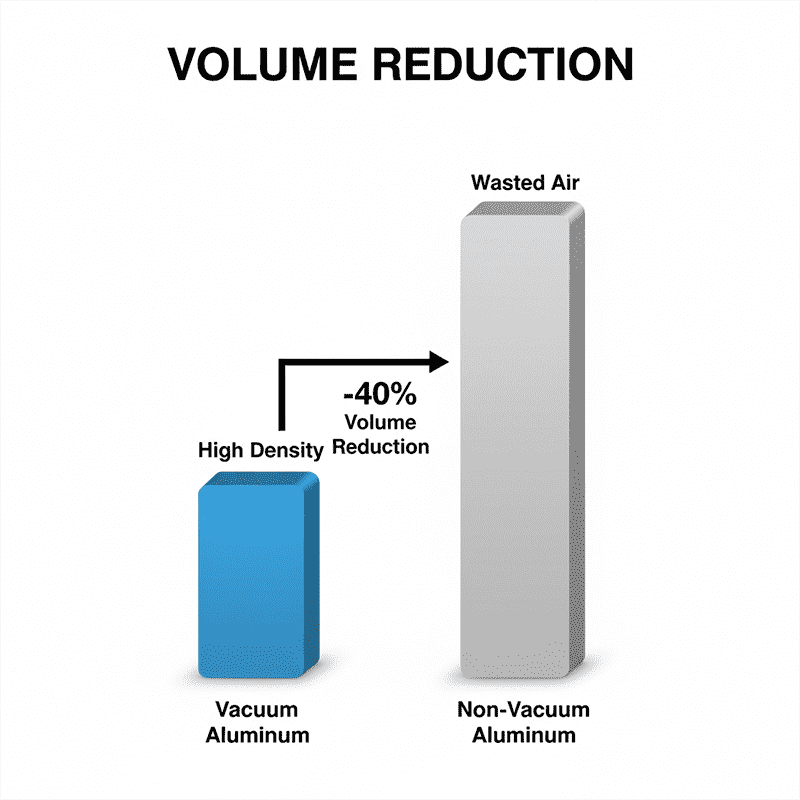

From a volumetric engineering perspective, high-barrier aluminum foil non-vacuum bags are inefficient. They retain their natural, loose bulk density. By processing the same product through a vacuum packaging machine, the volume is compressed by 30-40%. This compression, achieved through advanced vacuum sealing technology, significantly increases the mass-per-pallet ratio. When integrating automatic packaging systems, this density is a critical parameter. A standard packaging machine manufacturer might overlook this, but at Jialong, we know that using a vacuum packaging machine is essential for maximizing logistics density.

Odor Integrity: Absolute Isolation

Residual air can act as a carrier for odor molecules. A vacuum packaging machine ensures that there is no medium for internal odor diffusion or external cross-contamination. Combining high-barrier aluminum foil with active vacuum sealing technology offers the highest possible standard of protection available in automatic packaging systems.

View System SpecificationsConclusion: Technical Superiority Confirmed

While high-barrier aluminum foil is an excellent material, it cannot perform miracles on its own. It requires the active air removal of a vacuum packaging machine to reach full potential. For any serious manufacturer, relying on vacuum sealing technology is a technically sound investment. As a packaging machine manufacturer, we see the vacuum packaging machine as the core of modern preservation.

Speak with Our Engineers

We can demonstrate the performance difference of your material on our automatic packaging systems. Let us optimize your high-barrier aluminum foil application with the right vacuum packaging machine.

Engineer Consultation Visit Jialong Technology