Decoding Parallel Processing: How Multi-Station Design Redefines the Granular Vacuum Packaging Machine

Decoding Parallel Processing: How Multi-Station Design Redefines the Granular Vacuum Packaging Machine

Published on: January 9, 2026 | By Jialong Engineering Dept.

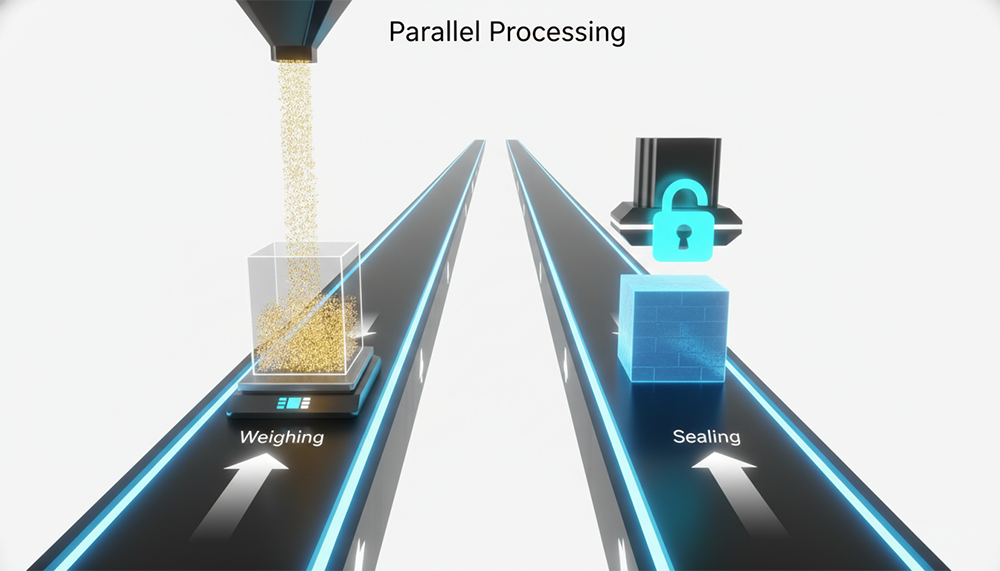

In the domain of bulk solid processing, specifically for materials like rice and chemicals, the bottleneck has historically been the serial nature of packaging. Traditional equipment performs filling, vacuuming, and sealing in a linear sequence at a single station. Jialong, a premier packaging machine manufacturer, has engineered a solution to this limitation with the multi-station granular vacuum packaging machine. This system utilizes parallel processing architecture, decoupling the feeding phase from the sealing phase to maximize cycle efficiency.

The structural innovation of our granular vacuum packaging machine lies in its grouped station layout. The first group focuses on the weighing and bagging machine function: precise feeding, metering, and bag clamping. Simultaneously, a secondary station group executes vacuum extraction and sealing. This parallel operation means that while one unit of the rice vacuum packaging machine is drawing a vacuum, the weighing and bagging machine unit is already preparing the next load. For an industrial automatic shaping packing machine, this eliminates idle time, resulting in a quantifiable leap in production throughput.

The shaping mechanism differentiates a standard bagger from an automatic shaping packing machine. Driven by pneumatic cylinders, four side plates and a bottom plate exert orchestrated pressure on the bag during the vacuum cycle. In a rice vacuum packaging machine, this transforms loose granules into a rigid geometric cube. This increases storage density by over 30%. As a packaging machine manufacturer, we ensure this process is seamless. The integration of this shaping capability within the granular vacuum packaging machine framework requires robust mechanical design to withstand repetitive stress.

Precision Control Systems

Our granular vacuum packaging machine incorporates electronic weighing systems with an error margin of ±0.2%. This precision in the weighing and bagging machine component is vital for material conservation. As a top packaging machine manufacturer, we couple this with PLC automated control.

View Technical SpecsConclusion: A Standard for Efficiency

The shift towards the multi-station granular vacuum packaging machine drives industry standardization. By integrating the functions of an automatic shaping packing machine with high-speed processing, we offer superior value. Jialong, as your packaging machine manufacturer, continues to refine this technology for the rice vacuum packaging machine market and beyond.

Consult Our Systems Engineers

We can optimize a granular vacuum packaging machine layout for your plant. Contact us to discuss the technical advantages of our automatic shaping packing machine series.

Engineer Consultation Visit Jialong Technology