Deconstructing the "Secondary Vacuum": The Engineering Behind High-Density Rice Shaping

Deconstructing the "Secondary Vacuum": The Engineering Behind High-Density Rice Shaping

Published on: January 23, 2026 | By Jialong Engineering Dept.

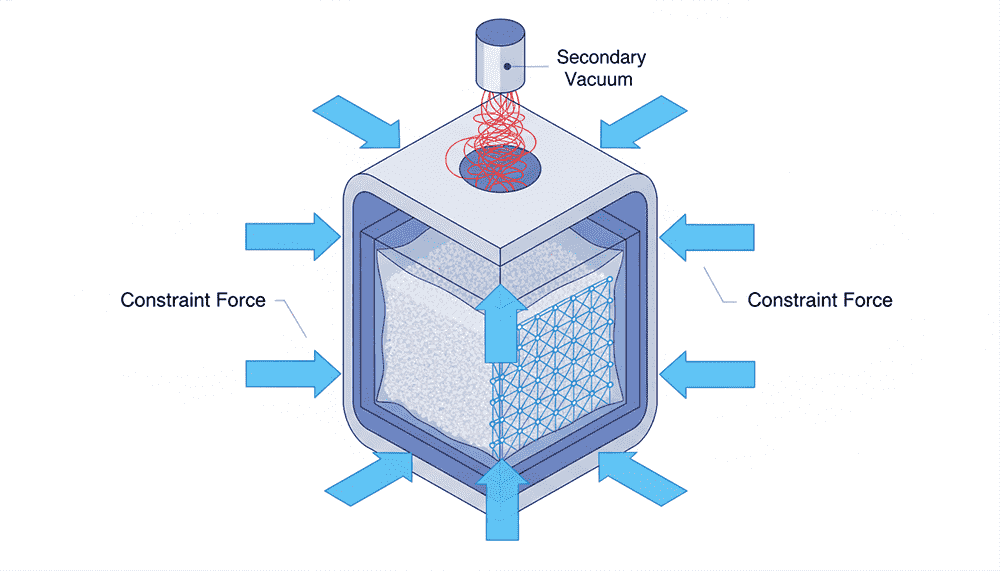

In the advanced grain processing sector, the rice vacuum packaging machine has evolved beyond simple atmospheric evacuation. The industry standard has shifted towards a specific subtype: the vacuum shaping machine. This technology addresses the fundamental limitations of loose vacuum bags—irregularity and poor stackability. The engineering breakthrough lies in a dual-phase process known as "Secondary Vacuuming" coupled with "Mold Constraint." This report, from the perspective of a dedicated packaging machine manufacturer, dissects the mechanics of how a brick shape packaging machine turns flowable grains into a structural unit.

Standard vacuuming collapses the bag onto the product, often freezing the grains in a chaotic arrangement. A brick shape packaging machine, however, operates differently. First, the bag is filled and subjected to an initial vacuum. Crucially, it is then enclosed within a rigid precision mold that defines the final cubic dimensions. The automatic vacuum packing machine then initiates a "Secondary Vacuum" phase. Under this deeper negative pressure, constrained by the mold walls, the rice grains are forced to re-orient into their densest possible packing arrangement (Maximum Geometric Density). This transforms the rice vacuum packaging machine from a sealer into a forming press.

The result of this process is a product that behaves like a solid block, not a fluid bag. This structural rigidity is essential for modern automated logistics. A well-calibrated vacuum shaping machine produces bricks that can be stacked high on pallets without slipping or deformation. As a packaging machine manufacturer, we stress test our automatic vacuum packing machine outputs to ensure they resist compression. This prevents grain breakage during transport. Integrating this level of shaping control is what separates a high-end brick shape packaging machine from entry-level equipment.

Precision Systems for Standardization

Achieving this level of consistency requires an automatic vacuum packing machine with high-tolerance molds and a powerful dual-stage pump system. Jialong is a packaging machine manufacturer specializing in this precision technology. Our vacuum shaping machine portfolio defines the standard for density.

View Technical SpecsConclusion: A Revolution in Form and Function

Vacuum molded packaging is indeed a revolution. By utilizing a brick shape packaging machine capable of secondary vacuuming, manufacturers can turn loose grain into a standardized industrial unit. As your packaging machine manufacturer, Jialong delivers the rice vacuum packaging machine technology that makes this transformation possible. Our vacuum shaping machine technology sets the global benchmark.

Consult Our Engineering Team

We can demonstrate the density improvements on your specific grain variety. Let's discuss your automatic vacuum packing machine requirements.

Engineer Consultation Visit Jialong Technology