A tour of a benchmark automated packaging and palletizing line reveals how JIALONG's robust solutions drive real-world efficiency and build unshakable client trust.

Zhangzhou, China – In the world of industrial automation, PowerPoint presentations and product catalogs can only tell part of the story. The true measure of a solution's worth is its performance under real-world operational pressure. Affirming this principle, Zhangzhou JIALONG Technology Co., Ltd. (hereafter "JIALONG Technology"), a leading provider of intelligent weighing and packaging automation systems, recently hosted an exclusive on-site technical tour for industry partners and prospective clients. The destination: the bustling factory floor of one of its long-standing, highly successful clients, offering a transparent, firsthand look at a JIALONG-engineered automated production line in full operation.

Chapter 1: The On-Site Experience – A Symphony of Precision and Power

Upon entering the client’s modern and spacious facility, visitors were greeted not by the chaotic noise of a traditional factory, but by the rhythmic, steady hum of machinery operating in perfect harmony. The centerpiece of the workshop is a complete, end-to-end automated packaging and palletizing line, a testament to JIALONG's system integration capabilities.

Viewed from an elevated platform, the line’s intelligent design and logical flow become strikingly clear. It appears as a metallic artery coursing through the facility, with silver conveyors, vibrant yellow safety guards, and signature teal-colored machinery creating a visually organized and efficient workspace. Material flows seamlessly from the towering silos above, down into the packaging units, along conveyors, and finally to the robotic palletizer. This is not just manufacturing; it is industrial art in motion.

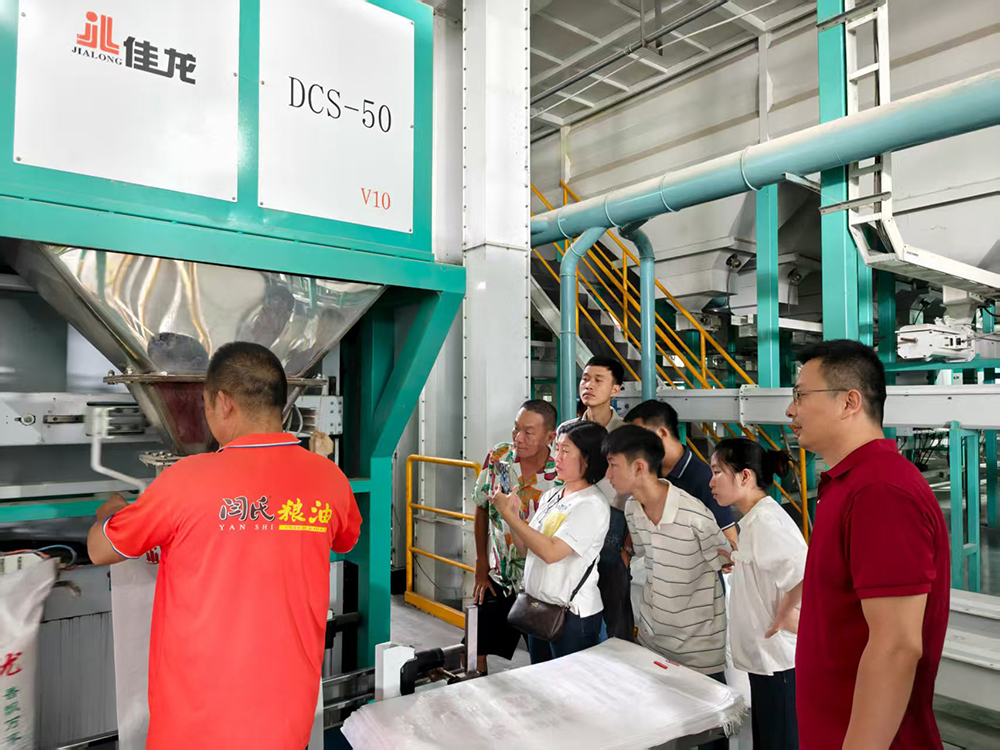

Gathering around a key component of the line, the JIALONG DCS-50 V10 Quantitative Packaging Scale, the visiting delegation listened intently to a lead technician from the host facility. The operator, clearly an expert on his equipment, demonstrated its functions with an air of confidence and pride that only comes from working with a reliable and efficient system day in and day out. The guests—a mix of engineers, procurement managers, and business owners—observed with focused attention, capturing video on their phones and examining the machine's build quality. Their expressions shifted from initial curiosity to clear approval, recognizing that they were witnessing a truly dependable production asset.

The tour then moved upstream, where the group observed the massive raw material feeding and conveying systems. Here, amidst the impressive scale of the infrastructure, an in-depth technical discussion unfolded between JIALONG's experts, the host factory's team, and the visitors. Topics ranged from handling materials with specific properties to optimizing line speed and ensuring system-wide compatibility. This open-dialogue approach underscores JIALONG's confidence, proving its willingness to showcase its solutions in the transparent and demanding environment of a live factory floor.

Chapter 2: A Deep Dive – How the "JIALONG Solution" Delivers Tangible Value

This impressive operation is powered by JIALONG Technology's holistic, customized approach to system integration. The production line is far more than a simple collection of machines; it is a meticulously engineered solution designed to solve specific industry pain points.

1. The Core of Precision: The DCS-50 Quantitative Packaging Scale

The DCS-50 scale is the first critical step in delivering significant ROI. It directly addresses the chronic issue of product giveaway and inconsistent package weights common in manual or semi-automated processes. By utilizing high-precision load cells and an advanced control algorithm, the DCS-50 achieves gram-level accuracy at high speeds, minimizing material waste and ensuring product quality consistency. This directly translates to substantial cost savings for the client.

2. The Engine of Efficiency: Fully Automated Conveying & Robotic Palletizing

If precision saves costs, automation multiplies output. In today's competitive landscape marked by rising labor costs and skilled worker shortages, automating strenuous, repetitive tasks is a strategic imperative. JIALONG's integrated line uses a series of smart conveyors, bag shaping units, and quality-check modules to seamlessly transport filled bags to the palletizing station. The industrial robot at the end of the line is the undisputed champion of efficiency. Operating 24/7 without fatigue, it stacks heavy bags with a level of speed, precision, and consistency that is impossible to replicate manually. This not only boosts throughput but also enhances workplace safety and gives the client greater production flexibility and scalability.

3. The Intelligent Brain: The Integrated Central Control System

Unifying these powerful hardware components is JIALONG's proprietary central control system. Acting as the "brain" of the operation, it provides a single, user-friendly interface for operators to manage the entire line. From one control panel, staff can initiate startup and shutdown sequences, adjust parameters, monitor real-time operational status, and receive proactive maintenance alerts. Furthermore, the system captures vital production data—such as output volume, cycle times, and uptime—providing management with the analytics needed for continuous improvement and a confident stride towards Industry 4.0.

Chapter 3: The Enduring Value – Trust Forged in Steel, Service Sealed with a Promise

What gives JIALONG Technology the confidence to use a client’s factory as its showroom? The answer is simple: trust. It is a trust built on a foundation of rock-solid product reliability and unwavering lifecycle support.

A satisfied customer is the most powerful endorsement. When potential partners see JIALONG equipment performing flawlessly year after year in a demanding, high-volume environment, it provides a level of assurance that no sales pitch can match. It silently communicates JIALONG's core promise: we are not just a one-time equipment vendor; we are a long-term strategic partner in our clients' success.

This partnership philosophy is embedded in JIALONG’s service model—from initial consultation and site survey, through custom engineering, meticulous manufacturing, professional installation, comprehensive training, and responsive 24/7 after-sales support. The confidence of the on-site operator in the photos is a direct reflection of this ecosystem of support. It is this unwavering commitment that turns customers into advocates, who are proud to showcase the technology that powers their success.

Conclusion: Paving the Path from Traditional Workshops to Smart Factories

This insightful tour offers just a glimpse into JIALONG Technology's capabilities. From grain and food processing to chemicals and building materials, JIALONG's automated systems are quietly powering essential industries across the globe.

In today's fast-evolving market, the transition to automation and intelligence is no longer an option—it is a necessity for survival and growth. With its deep technical expertise, innovative spirit, and client-centric philosophy, Zhangzhou JIALONG Technology stands ready as the ideal partner to guide enterprises on this critical journey.

Because at the end of the day, seeing is truly believing. JIALONG Technology will continue to forge ahead, working hand-in-hand with its global partners to transform traditional workshops into the smart, efficient, and resilient factories of the future.