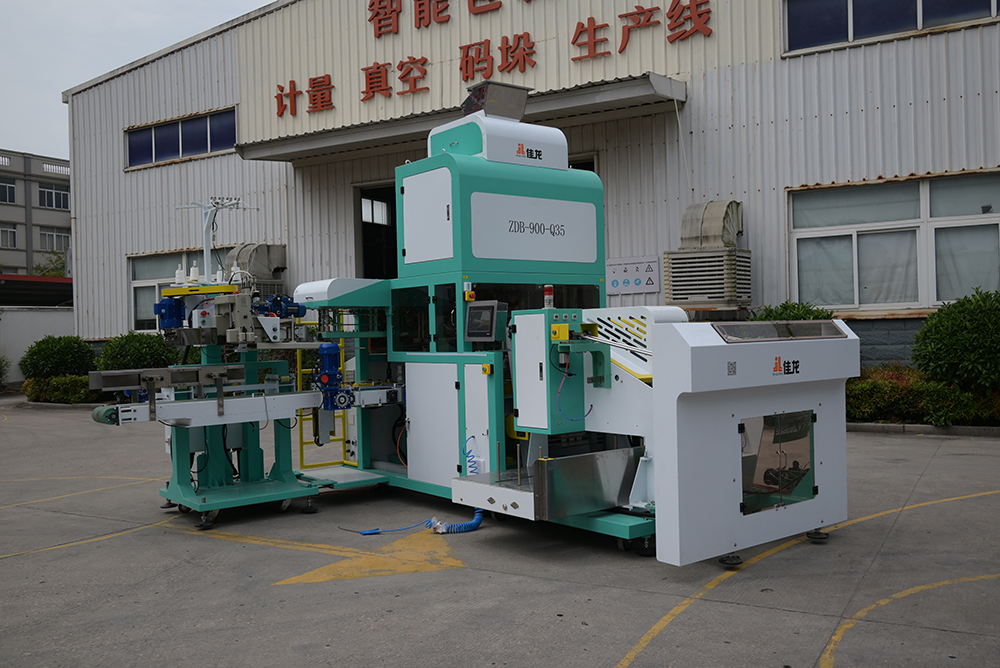

Introducing the Jialong ZDB-900-Q35: The Next-Generation Automated Bagger for Elite Production Lines

Introducing the Jialong ZDB-900-Q35: The Next-Generation Automated Bagger for Elite Production Lines

Deconstructing the ZDB-900-Q35's Advanced Operational Workflow

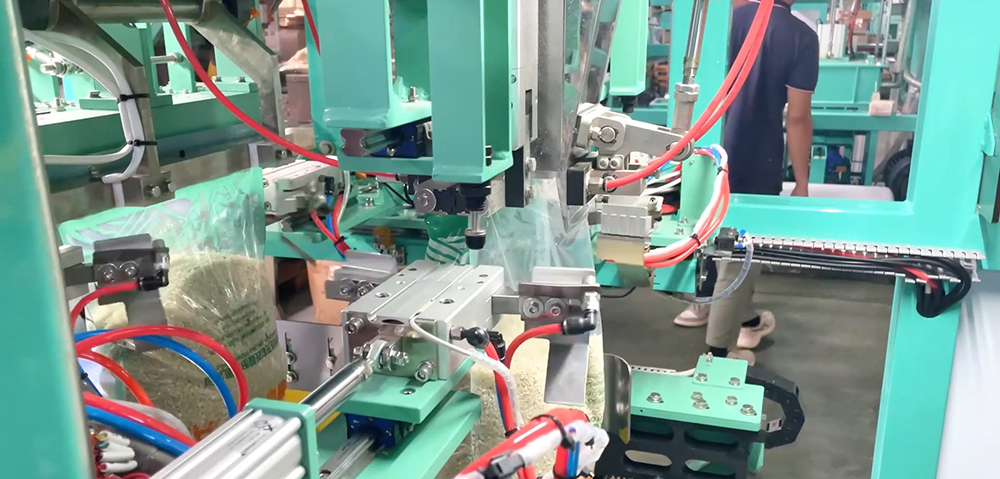

Autonomous Bag Dispensing: The cycle begins at a horizontal magazine, where pre-formed bags are systematically fed. A robotic arm, equipped with a sophisticated sensor-driven vacuum system, ensures that a single bag is flawlessly separated and presented for the next stage, virtually eliminating jams and misfeeds. Precision Opening and Filling: The selected bag is securely gripped and pneumatically opened to its full dimensions before being perfectly aligned under the filling nozzle. An integrated, high-sensitivity weighing apparatus then dispenses a precise measure of granular product (from 5-25 kg), a crucial feature for any automatic bagger for granules focused on minimizing product giveaway. Content Compaction and Sealing: Following the fill, a controlled vibration module settles the material within the bag, optimizing density for better palletization and transport. The bag then proceeds to a high-integrity sealing station, where consistent heat and pressure are applied to create a hermetic, factory-grade seal, safeguarding product quality. Intuitive System Command Center: At the core of the ZDB-900-Q35 lies a powerful PLC from a world-class supplier, managed via a user-centric color HMI. This interface allows for effortless setup of new jobs, real-time performance monitoring, and rapid diagnostics, empowering staff to operate the system with minimal training.

What Key Business Challenges Does This System Overcome?

Solving the Human Resource Gap: This heavy-duty packaging automation system significantly reduces dependency on manual labor. It addresses the issues of rising wages, skill shortages, and the inherent inconsistencies of human work, allowing for a more predictable and streamlined production flow. Shattering Production Ceilings: The ability to operate continuously at 900 bags per hour provides businesses with the sheer capacity needed to pursue larger contracts, reduce lead times, and confidently manage seasonal peaks without requiring overtime or temporary staff. Enhancing Financial Performance: The system's design directly impacts profitability. By ensuring pinpoint weight accuracy, slashing labor expenditures, and operating with maximum uptime, the ZDB-900-Q35 offers an exceptionally swift return on investment. Guaranteeing Brand and Product Integrity: Every bag that exits the machine is a testament to quality. The uniform weight, professional appearance, and robust seal ensure that the end customer receives a product that reflects the high standards of your brand.

Broad Industry Applicability and Versatility

Food & Agri-business: From rice and grains to seeds and pet food. Chemical & Plastics: For handling resins, pellets, and various mineral powders. Construction & Minerals: Effectively bagging dry mortars, sands, and similar materials. And more, for any industry requiring high-volume bagging of free-flowing granular products.

About Jialong: A Commitment to Engineering Excellence

Website: [www.easypackingmachine.com]

Sales Inquiry Email: [export@jialong.cn] Direct Phone: [+86-13906062253]