Mitigating Hygroscopic Caking: The Technical Imperative for Vacuum Packaging Salt and Powders

Mitigating Hygroscopic Caking: The Technical Imperative for Vacuum Packaging Salt and Powders

Published on: November 14, 2025 | By Jialong Engineering Dept.

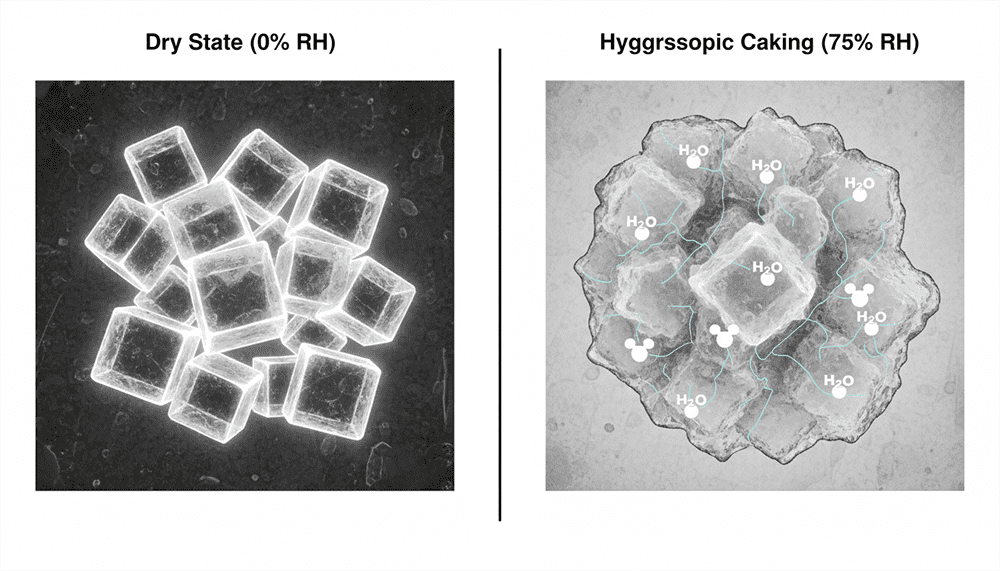

Table salt (Sodium Chloride) is a classic example of a hygroscopic crystalline material. Its tendency to absorb atmospheric moisture, leading to clumping and caking, presents a significant challenge in packaging. This phenomenon is not unique to salt; it affects a vast range of industrial and food-grade powders. From a technical standpoint, the solution requires a system that controls the atmospheric conditions within the package. This is the primary function of a modern powder packing machine with vacuum capabilities, a cornerstone of advanced food packaging machinery.

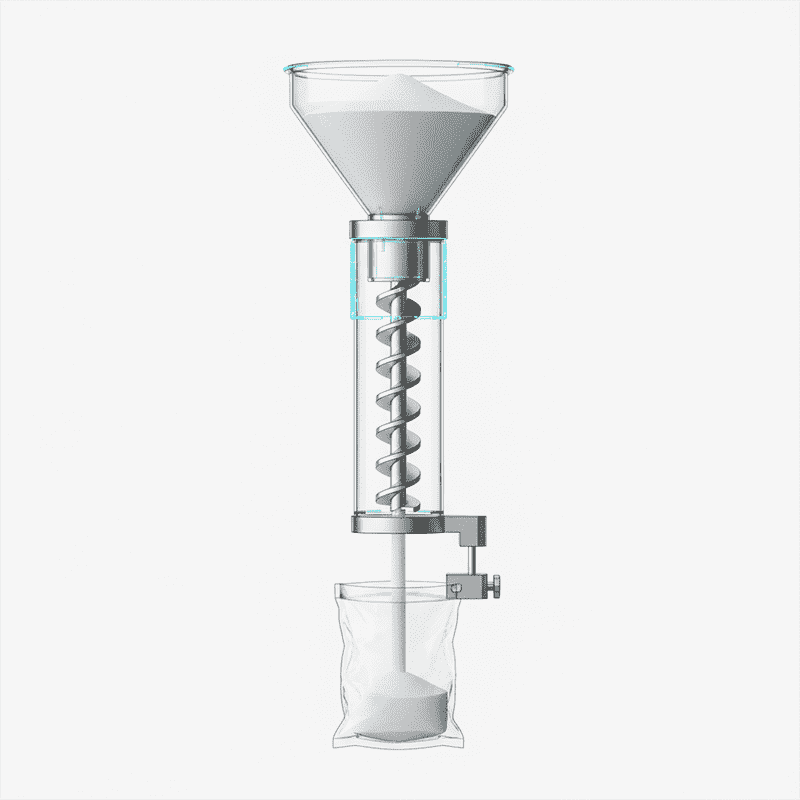

An effective solution requires two distinct technical capabilities. First, precise dosing is achieved using a high-accuracy auger filler. This component ensures each package contains the exact target weight. Second, a vacuum system removes the moisture-laden air before the final seal is made. An advanced powder packing machine integrates both functions seamlessly. The auger filler meters the product, and the vacuum system creates the protective environment. This is a core design philosophy at our packaging machine factory.

For industrial-scale operations, a standalone powder packing machine is insufficient. The solution must be part of integrated automatic packaging systems. This involves automated feeding of the product to the auger filler, bag presentation, and downstream conveying. As an experienced packaging machine factory, we design complete lines. The efficiency of the automatic packaging systems is as important as the performance of the core powder packing machine itself, and we are experts in this field of food packaging machinery.

Protecting Additives and Nutrients

Beyond preventing caking, vacuum sealing protects vital additives. In iodized salt, the iodine can degrade through oxidation. Removing oxygen with a proper food packaging machinery solution preserves these micronutrients. This principle applies to a vast range of fortified powders and specialty chemicals where the stability of additives is critical.

Explore Powder SolutionsConclusion: A Fundamental Technology for Powder Handling

The challenges presented by hygroscopic materials like salt necessitate an advanced engineering solution. A powder packing machine equipped with a precision auger filler and vacuum capability is that solution. As a leading packaging machine factory, we specialize in building food packaging machinery and automatic packaging systems that provide this fundamental level of protection and efficiency. Our expertise ensures a superior outcome.

Consult With Our Powder Handling Specialists

Let our engineers analyze the properties of your specific powder and recommend the ideal auger filler configuration and automatic packaging systems to ensure its integrity and your production efficiency.

Connect with an Engineer Visit Jialong Technology