The Physics of Powder: Overcoming Oxidation and Compaction in Industrial Flour Packaging

The Physics of Powder: Overcoming Oxidation and Compaction in Industrial Flour Packaging

Published on: January 30, 2026 | By Jialong Powder Engineering Dept.

In the hierarchy of food processing, flour presents a unique volatility challenge. Unlike whole grains, the milling process exposes a massive surface area to oxygen. This exposure accelerates lipid oxidation. For manufacturers, the traditional woven sack is no longer a viable vessel for industrial flour packing. To truly prevent flour rancidity, the industry must pivot toward advanced powder packaging technology. However, vacuuming powder is fundamentally different from vacuuming grain. This report deconstructs how a specialized flour vacuum packaging machine operates to extend flour shelf life and why standard equipment fails.

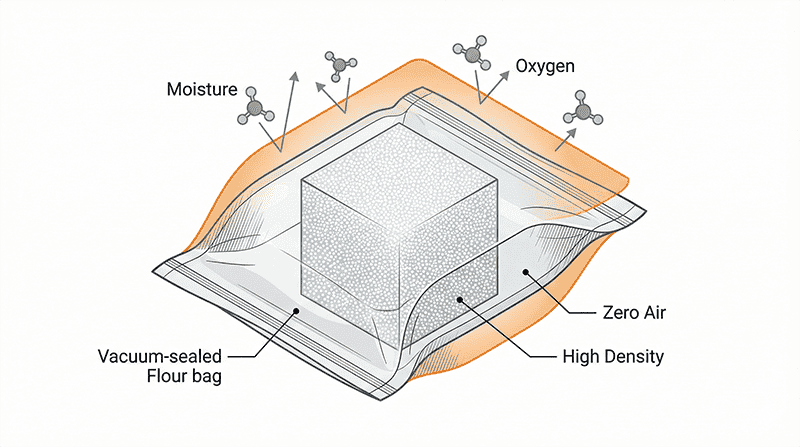

Figure 1: The vacuum process densifies the flour structure without damaging gluten integrity.

Why does flour go bad? The culprit is the wheat germ oil remaining in the flour. When exposed to oxygen, these lipids break down. To prevent flour rancidity effectively, you must remove the oxygen. This is the core function of industrial flour packing using vacuum bricks. By creating a negative pressure environment, we pause the chemical reaction. Engineering data suggests that using a proper flour vacuum packaging machine can extend flour shelf life by approximately 50% to 100%.

This preservation is critical for export markets. Without robust powder packaging technology, the product arriving at the destination is chemically distinct from the product that left the factory. Therefore, to extend flour shelf life significantly, reliance on woven bags must end. The shift to vacuum-based industrial flour packing is scientifically inevitable for premium brands aiming to prevent flour rancidity.

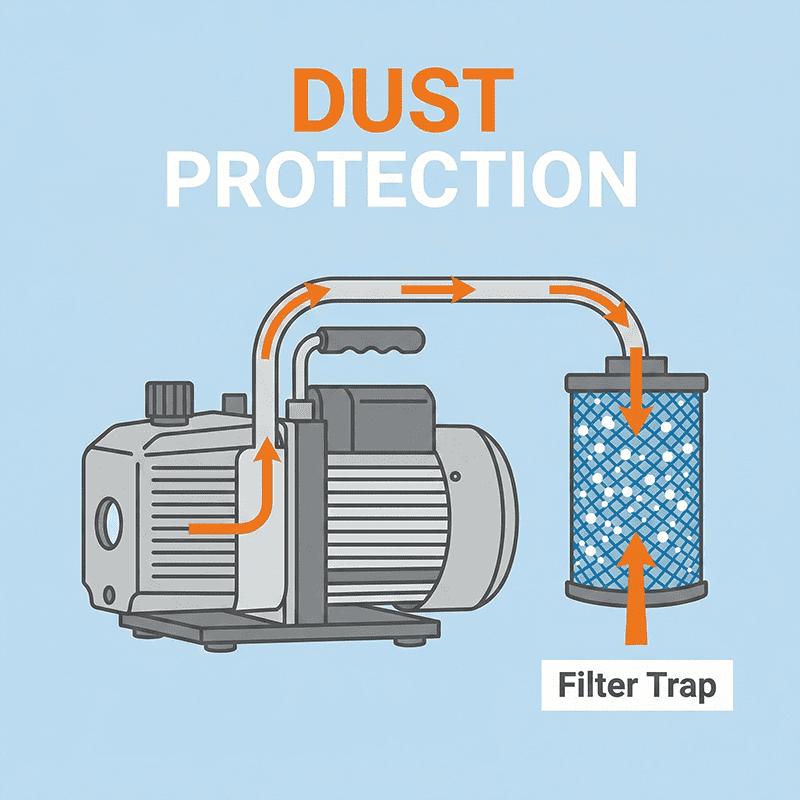

Flour is a fine dust. When you apply vacuum, the airflow carries particles. Standard machines fail here. A Jialong flour vacuum packaging machine is equipped with specialized filtration. This specific powder packaging technology isolates dust before it reaches the pump. If you want to extend flour shelf life without destroying your equipment, you need this filtration.

General packaging machines cannot handle industrial flour packing because the dust mixes with pump oil. Our dedicated flour vacuum packaging machine uses a vertical settling design. This ensures the powder packaging technology works reliably, helping manufacturers prevent flour rancidity without downtime. It is a precise balance of suction and filtration required for high-volume industrial flour packing.

Figure 2: Multi-stage filtration is essential for vacuuming fine powders.

Beyond chemistry, there is physics. Industrial flour packing in loose bags creates unstable pallets. Vacuum processing turns this fluid into a solid brick. This stability helps prevent flour rancidity by keeping the seal intact. Advanced powder packaging technology ensures these bricks are uniform.

Furthermore, to extend flour shelf life, the package must remain airtight during shipping. The rigid brick created by our flour vacuum packaging machine prevents friction damage. This represents the pinnacle of modern powder packaging technology. By adopting this method of industrial flour packing, you secure both the product quality and the transport safety, ultimately acting to prevent flour rancidity throughout the supply chain.

Conclusion: The New Standard

The transition to vacuum-based industrial flour packing is not a trend; it is the future. By addressing dust filtration with proper powder packaging technology, the Jialong flour vacuum packaging machine offers a comprehensive solution. If your goal is to prevent flour rancidity and significantly extend flour shelf life, this technology is non-negotiable.

Request a Powder Handling Consultation

We can demonstrate our dust-proof flour vacuum packaging machine with your specific product.

Engineer Consultation Visit Jialong Website