The Science of a Perfect Seal: A Deep Dive into the Sealing Technology of a Vacuum Sealer Machine

The Science of a Perfect Seal: A Deep Dive into the Sealing Technology of a Vacuum Sealer Machine

Published on: December 10, 2025 | A Jialong Engineering Whitepaper

In vacuum packaging, the vacuum process creates the preservation environment, but the sealing process is what guarantees its longevity. A seal failure renders the entire process useless. The technology responsible, the food packaging sealing machine, is arguably the most critical component within any vacuum sealer machine. Achieving a perfect, hermetic seal is a science, a delicate interplay of precisely controlled temperature, pressure, and time. This analysis deconstructs these core technical pillars.

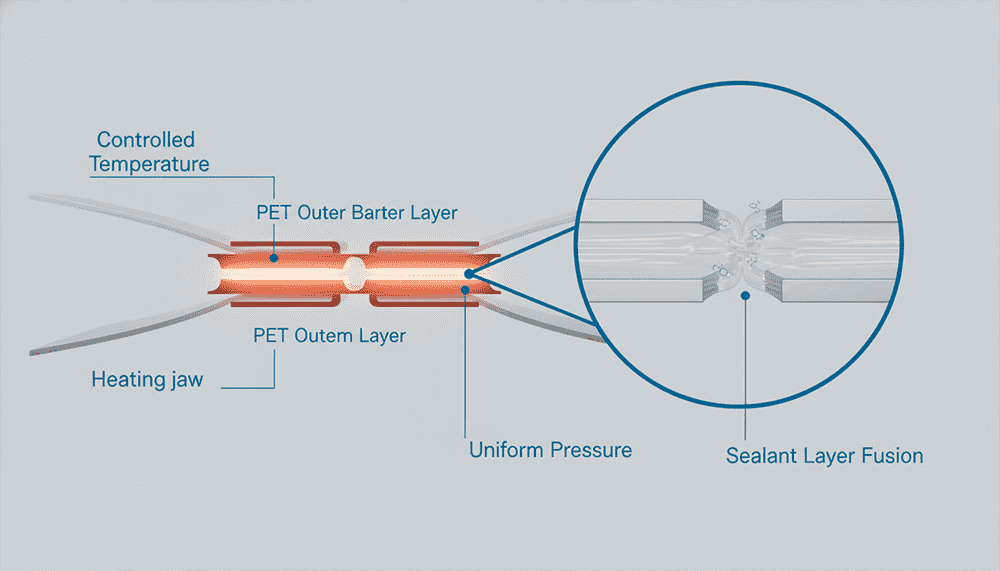

The goal is to melt the inner sealant layer (e.g., PE) without compromising the outer barrier layers. An advanced food packaging sealing machine achieves this with PID controllers that maintain heating element temperatures to within ±1-2°C. A quality packaging machine manufacturer selects heating strip materials (e.g., nichrome) for uniform thermal distribution, preventing hotspots that can cause leaks. This level of control is fundamental to a reliable food vacuum sealer machine and all automatic packaging systems.

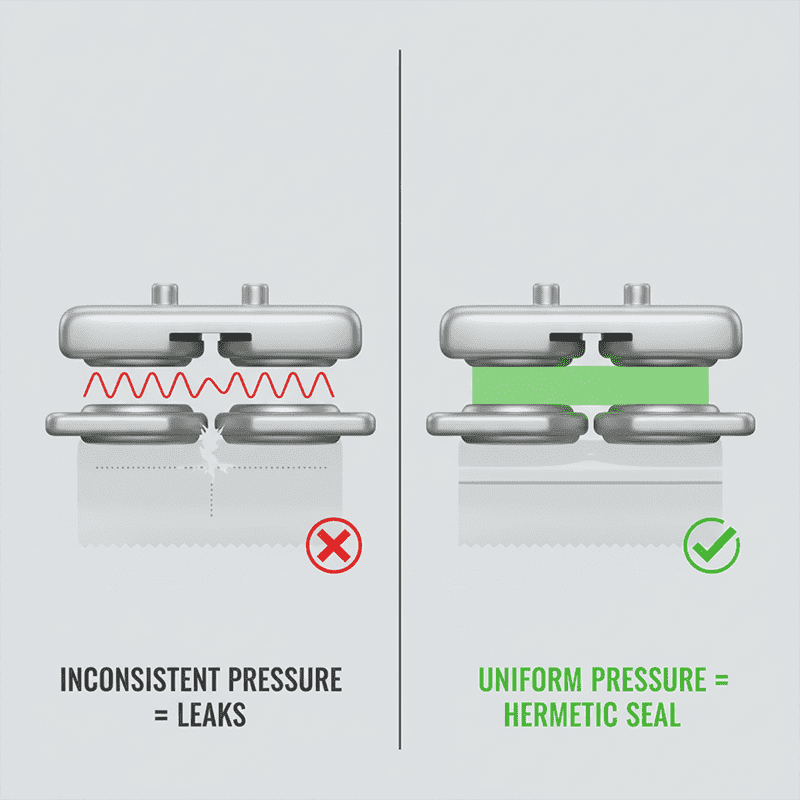

Temperature alone is not enough. The mechanical system of the food packaging sealing machine must apply consistent, uniform pressure across the entire seal area for a specific duration (dwell time). Pneumatic actuators controlled by precise solenoids are superior to simpler spring-loaded systems. This ensures the molten layers fuse completely without voids or weak points. Any serious packaging machine manufacturer invests heavily in the mechanical rigidity and control of the sealing jaw assembly of their vacuum sealer machine. This is what makes a professional food vacuum sealer machine so robust.

Pillar 3: Material and Condition Adaptation

A truly intelligent food packaging sealing machine can adapt. Its control system must allow for easy adjustment of parameters to match different film types (PE, foil composites, etc.) and thicknesses. Furthermore, advanced automatic packaging systems feature sensors that can detect contaminants like moisture on the seal area and dynamically compensate by increasing temperature or dwell time. This adaptive capability is what defines a top-tier food vacuum sealer machine and is essential for reliable, high-speed automatic packaging systems. A smart vacuum sealer machine makes a big difference.

Explore Our TechnologyConclusion: A System Engineered for Integrity

The seal is not a simple action but the result of a complex engineering system. As an expert packaging machine manufacturer, we believe the heart of a great vacuum sealer machine is its sealing system. Every component in our food vacuum sealer machine models is designed to work in concert to deliver this one critical outcome: a perfect, reliable seal. This philosophy extends to all our automatic packaging systems.

Consult Our Sealing Application Experts

Discuss your specific film materials and quality requirements with our specialists. We can recommend the ideal food packaging sealing machine to guarantee the integrity of your products.

Connect with an Engineer Visit Jialong Technology