- Jialong

- China

- 30 working days

- 20 sets per month

Ton Bag Packing Machine Jumbo Bag Weighers, Bulk packing machine, bulk bag packing machine

Gravity feeding mechanism, high-speed loading, greatly increasing output.

Use an automatic bag removal mechanism to reduce labor intensity.

Imported technology touch screen, weighing control instrument, weighing sensor, pneumatic actuator.

Equipped with high-precision AC regulated power supply to ensure stable and reliable operation.

Parts in touch with materials are made of imported stainless steel to make sure a long service life.

Reserved RS232/485 serial port for data communication with the peripheral management system.

Conveyor is optional.

LCS-60T-CQ1

Ton Bag Packing Machine Jumbo Bag Weighers

Applications:

Small particle material large-quantity quantitative packaging

500-1000KG Granular Bulk Packing Machine

Technical Parameters:

Model | LCS-60T-CQ1 |

Weighing range (kg) | 500~1000 |

Packing speed (bag/h) | 30~50 |

Interval value (g) | 100 |

Accuracy grade | X(0.2) |

Air consumption | 0.4~0.6MPa 1m3/h |

Power consumption | AC 380V 50Hz 2.8KW |

Install height (mm) ) | 3800 |

Main configuration

Name | Brand |

Weighing controller | Canada/Gerenral Measure |

Load cell | American/Celtron |

Power switch | Japan/Omron |

Limit switch | Japan/Omron |

Miniature circuit breaker | France / Schneider |

Button,knobs | France / Schneider |

Intermediate relay | France / Schneider |

Cylinder | Taiwan/Airtac |

Solenoid value | Taiwan/Airtac |

voltage-stabilized source

| Zhejiang/China |

Functions and Features:

1, Gravity feeding mechanism, high-speed loading, greatly increasing output.

2, Automatic bag removal mechanism to reduce labor intensity. bulk bag packing machine

3, Imported technology touch screen, weighing control instrument, weighing sensor, pneumatic actuator.

4, Equipped with high-precision AC regulated power supply to ensure stable and reliable operation.ton bag packing machine

5, Parts in touch with materials are made of stainless steel to make sure a long service life.

6, Reserved RS232/485 serial port for data communication with peripheral management system.

7, Conveyor is optional.500-1000KG Granular Bulk Packing Machine, Bulk packing machine

Detailed description:

Ton Bag Packing Machine Jumbo Bag Weighers, The quantitative scale is strictly in accordance with the national QB/T2501-2000 "Gravity Automatic Loading Scale" standard. The feeding mechanism adopts the secondary gate feeding mode, make sure fast feeding speed and the high precision. The weighing mechanism with high-precision load cell can ensure good performance and stable and reliable operation. The quantitative scale adopts the design of the bucketless scale, that is, the weighing is directly filled into the packaging bag to avoid the viscosity of the material, the precision problem caused by the residual cylinder, and the dust problem caused by the discharge of the measuring cylinder, and at the same time Effectively reduce the installation height. The hook part and the bag part adopt an automatic decoupling mechanism, and the bag is automatically hooked after the filling is completed, thereby reducing labor and reducing labor intensity.

The weighing scale adopts a weighing control instrument, which is one of the leading suppliers in the global precision instrumentation manufacturing industry. The weighing instrument professional instrument produced by Canada's Jermaine's production center and technical service center in China-China-Canada joint venture General Technology The instrument is based on the experience of research and development and production of electronic weighing and new automatic instruments for decades. After continuous innovation and improvement, it has advanced automatic drop correction function and multiple digital filtering. Functional high-precision weighing control instrument. The entire weighing process is controlled by high-performance weighing instruments and Siemens PLC programs in addition to manual bagging to ensure stable and reliable operation. The display part of the control instrument adopts a fluorescent double display, which is clear and intuitive. It has the functions of automatic error correction, super low error alarm and fault diagnosis. It can set 9 preset values to adapt to different materials and packaging specifications. The RS232/485 serial port can be used for data communication with the peripheral management system.

The weighing scale can be equipped with conveyor SJ-4500, which can transport materials out of the packaging station。

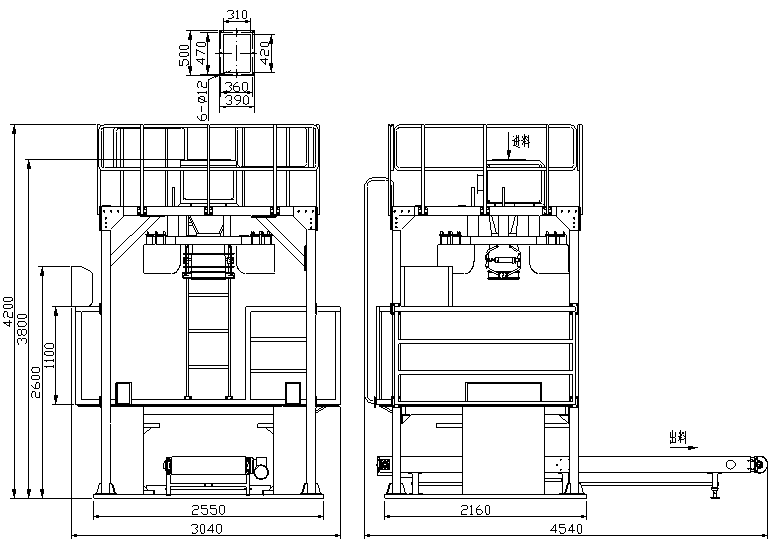

Picture:

Diagram: