Seal Integrity Analysis: Why PE Zipper Bags Fail Where Vacuum Packaging Machines Excel

Seal Integrity Analysis: Why PE Zipper Bags Fail Where Vacuum Packaging Machines Excel

Published on: December 26, 2025 | By Jialong Engineering Dept.

In the engineering of product preservation, the method of enclosure is the critical variable. While Polyethylene (PE) bags with zipper seals provide resealability, they lack the barrier properties required for industrial shelf-life standards. A professional `vacuum packaging machine`, utilizing `high-barrier packaging` films, operates on a fundamentally different principle: total atmospheric evacuation. This analysis by Jialong, a leading `packaging machine manufacturer`, dissects why `hermetic sealing technology` is non-negotiable for moisture-sensitive goods, and how it is implemented in `automatic packaging systems`.

PE material inherently possesses high moisture permeability. Even with a zipper closure, standard PE bags allow ambient humidity ingress, leading to a product clumping rate as high as 20-30%. In contrast, a `vacuum packaging machine` employs `hermetic sealing technology` to heat-fuse `high-barrier packaging` films (often PA/PE composites). This creates a zero-transmission environment. For a `packaging machine manufacturer`, the data is clear: to keep clumping below 1%, `automatic packaging systems` utilizing vacuum pressure are the only viable solution for hygroscopic materials. The seal created by a `vacuum packaging machine` is permanent and absolute.

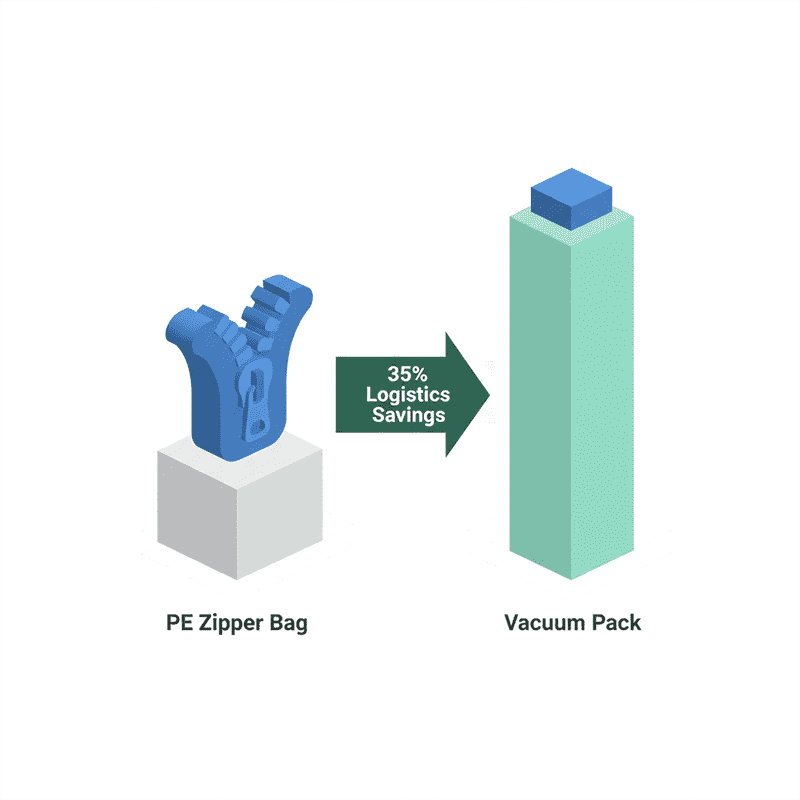

Loose-filled PE zipper bags retain interstitial air, resulting in "fluffy" packaging that consumes excess volume. A `vacuum packaging machine` mechanically removes this air, compressing the product volume by 30-40%. As a `packaging machine manufacturer`, we engineer `automatic packaging systems` to produce dense, brick-shaped units. This densification allows for 25-35% more product mass per transport unit compared to PE bags. Utilizing `hermetic sealing technology` not only protects the product but significantly optimizes logistics physics. `High-barrier packaging` combined with compression is the standard for efficiency.

Defining Shelf Life: 6 Months vs 18 Months

The presence of oxygen in PE zipper bags limits shelf life to roughly 6 months due to oxidation. Using a `vacuum packaging machine` with `high-barrier packaging` creates an anaerobic environment, extending shelf life to 12-18 months. `Hermetic sealing technology` is the only way to guarantee long-term stability in `automatic packaging systems`.

View Shelf-Life DataConclusion: Technical Superiority of Vacuum Systems

For manufacturers, the choice is technical reliability versus perceived convenience. A `vacuum packaging machine` provides measurable superiority in moisture resistance, volume reduction, and shelf life. Jialong, as a `packaging machine manufacturer`, advocates for `high-barrier packaging` within `automatic packaging systems`. Only `hermetic sealing technology` offers true industrial-grade protection.

Consult Our System Engineers

Transitioning from zipper bags to vacuum bricks requires system analysis. Let our engineering team design your `automatic packaging systems` centered around a robust `vacuum packaging machine`.

Talk to an Engineer Visit Jialong Technology