Volumetric Efficiency & Barrier Integrity: Comparing Brick Shape Packaging Machine Output vs. Traditional Rigid Cartons

Volumetric Efficiency & Barrier Integrity: Comparing Brick Shape Packaging Machine Output vs. Traditional Rigid Cartons

Published on: December 24, 2025 | By Jialong Engineering Dept.

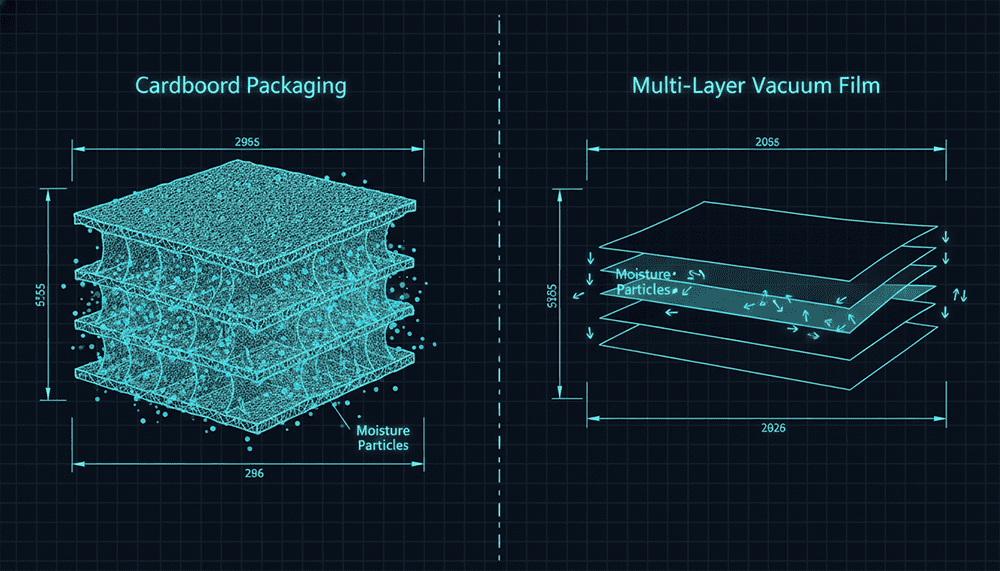

In the bulk packaging of hygroscopic materials such as cat litter, grains, and coffee, the choice between flexible vacuum bricks and rigid cartons with liners is a critical engineering decision. While cartons offer structural rigidity, they often fail in barrier performance. The technological solution lies in the brick shape packaging machine. Unlike loose liners which allow air retention, a high-precision vacuum packaging machine actively evacuates the atmosphere. This report analyzes why a packaging machine factory engineers systems for vacuum compaction over box filling.

Data indicates that cartons with simple PE/non-woven liners exhibit a 15-25% clumping rate for hygroscopic products. The fundamental flaw is the permeability of the cardboard and the incomplete seal of the liner. Conversely, an automatic packaging machine integrated with a heavy duty vacuum sealer module creates a near-perfect hermetic environment. By using a brick shape packaging machine to form the product, the internal void volume is minimized, leaving no space for residual air. This vacuum packaging machine technology is the only viable defense against high-humidity storage conditions, vastly outperforming carton systems.

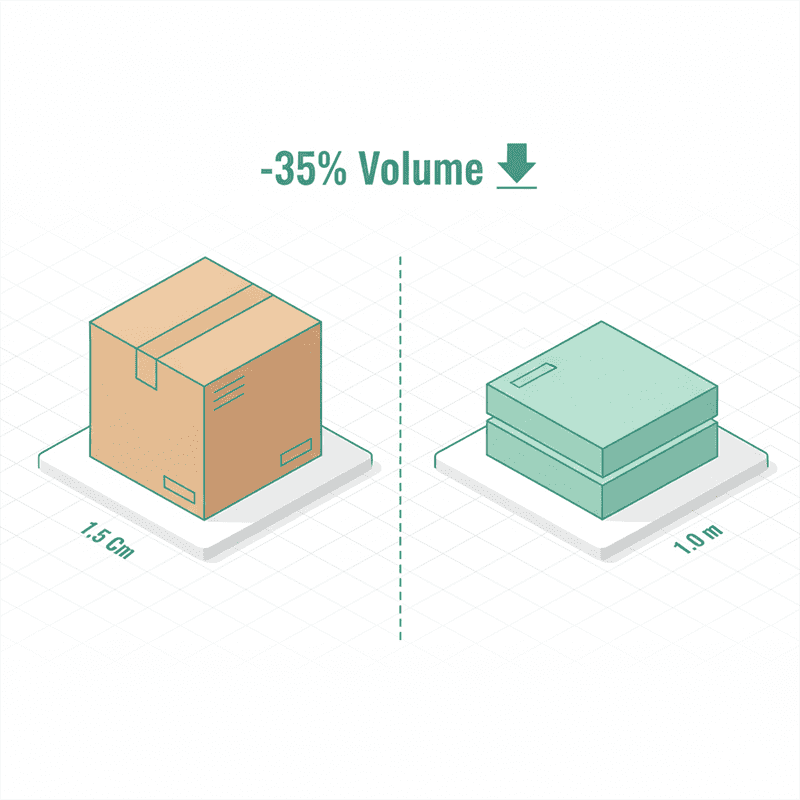

From a logistics engineering standpoint, space is cost. A rigid carton has a fixed volume regardless of contents. A brick shape packaging machine utilizes multi-axis compression to reduce product volume by 30-40% compared to loose fill. This enables an automatic packaging machine line to produce stackable units that maximize pallet density. Our packaging machine factory tests show that replacing cartons with vacuum bricks reduces transport volume by one-third. Using a vacuum packaging machine and heavy duty vacuum sealer technology converts packaging from a passive container into an active logistical asset.

The Integration of Heavy Duty Sealing

Odor cross-contamination is a major failure mode in mixed-use warehousing. An automatic packaging machine equipped with a heavy duty vacuum sealer eliminates this risk. Cartons are porous; vacuum films are not. A specialized brick shape packaging machine creates an impenetrable barrier. As a packaging machine factory, we ensure our systems meet the highest industrial standards.

View Technical SpecsConclusion: Technical Superiority of Vacuum Bricks

The engineering data is conclusive: for shelf life, density, and integrity, a brick shape packaging machine outperforms carton-and-liner solutions. Utilizing a heavy duty vacuum sealer within an automatic packaging machine line minimizes OTR (Oxygen Transmission Rate). Jialong is a packaging machine factory dedicated to advancing vacuum packaging machine technology for industrial applications.

Consult Our System Engineers

Analyze your barrier requirements with us. Whether you need a standalone heavy duty vacuum sealer or a complete automatic packaging machine line, our engineering team can provide the solution. Contact the packaging machine factory experts.

Engineer Consultation Visit Jialong Technology