Standardized Maintenance Protocols: Maximizing the Lifespan of Your Rice Vacuum Packaging Machine

Standardized Maintenance Protocols: Maximizing the Lifespan of Your Rice Vacuum Packaging Machine

Published on: January 26, 2026 | By Jialong Technical Dept.

The durability of industrial packaging equipment is defined not only by its manufacturing quality but also by the rigor of its upkeep. For a high-performance rice vacuum packaging machine, daily operational stress requires a disciplined counter-strategy: a comprehensive preventive maintenance schedule. Neglecting minor components like the sealing jaw integrity or the vacuum pump oil can lead to catastrophic system failures. This technical guide codifies the essential cleaning and inspection procedures required to maintain factory-spec performance.

Figure 1: Routine inspection of the rice vacuum packaging machine prevents downtime.

Contamination is the primary cause of mechanical friction. To protect the rice vacuum packaging machine, operators must wipe the exterior, the sealing jaw, and the vacuum chamber daily using a soft, dry cloth. Rice residue acts as an abrasive agent if left unchecked. For stubborn stains on the industrial packaging equipment, use a mild detergent, strictly avoiding corrosive agents that damage surface coatings.

Furthermore, the air filter (if equipped) is a vital lung for the system. A clogged filter increases load on the motor. The preventive maintenance schedule dictates that the filter must be cleared of dust particles or replaced immediately if damaged. Additionally, clearing the hopper prevents grain jamming, which protects the internal feeding mechanisms of the rice vacuum packaging machine.

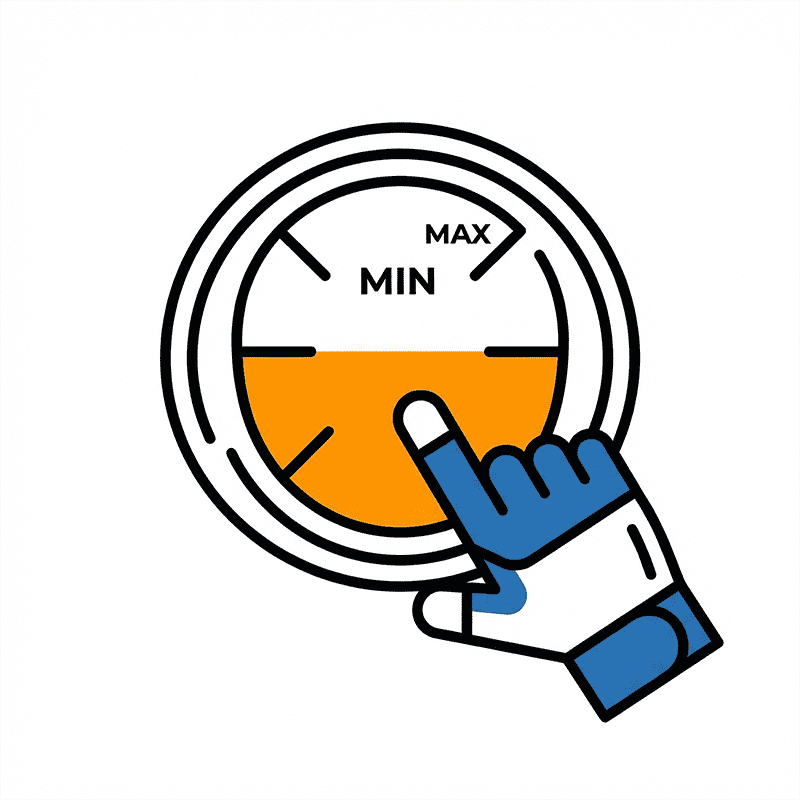

The vacuum pump is the costliest component to replace. Its longevity depends entirely on vacuum pump oil management. The preventive maintenance schedule requires daily verification that the oil level sits between the "MIN" and "MAX" marks. Running the rice vacuum packaging machine with low or contaminated vacuum pump oil will cause irreversible vane damage.

Simultaneously, operators must assess sealing jaw integrity. Check the sealing strip for wear, deformation, or cracks. A compromised strip results in air leakage, rendering the vacuum process useless. If sealing jaw integrity is found to be lacking, immediate replacement is mandatory. Finally, inspect power cords for fraying and test the emergency stop button to ensure the industrial packaging equipment shuts down instantly upon activation.

Figure 2: Proper vacuum pump oil levels are critical for performance.

Download the Full Maintenance Checklist

Ensure your rice vacuum packaging machine meets global standards. Jialong offers detailed guides on vacuum pump oil selection and sealing jaw integrity testing.

View Spare Parts & ToolsConclusion: Reliability Through Routine

Implementing a strict preventive maintenance schedule transforms industrial packaging equipment from a variable cost into a reliable asset. By proactively managing vacuum pump oil and sealing jaw integrity, you ensure the Jialong rice vacuum packaging machine delivers consistent results year after year.

Engineering Support & Consultation

Do not wait for a breakdown. Contact our engineering team for advice on maintaining your rice vacuum packaging machine.

Consult an Engineer Visit Jialong Website