The Engineering Superiority of Six-Sided Shaping in Vacuum Packaging Technology

The Engineering Superiority of Six-Sided Shaping in Vacuum Packaging Technology

Published on: November 7, 2025 | By Jialong Engineering Dept.

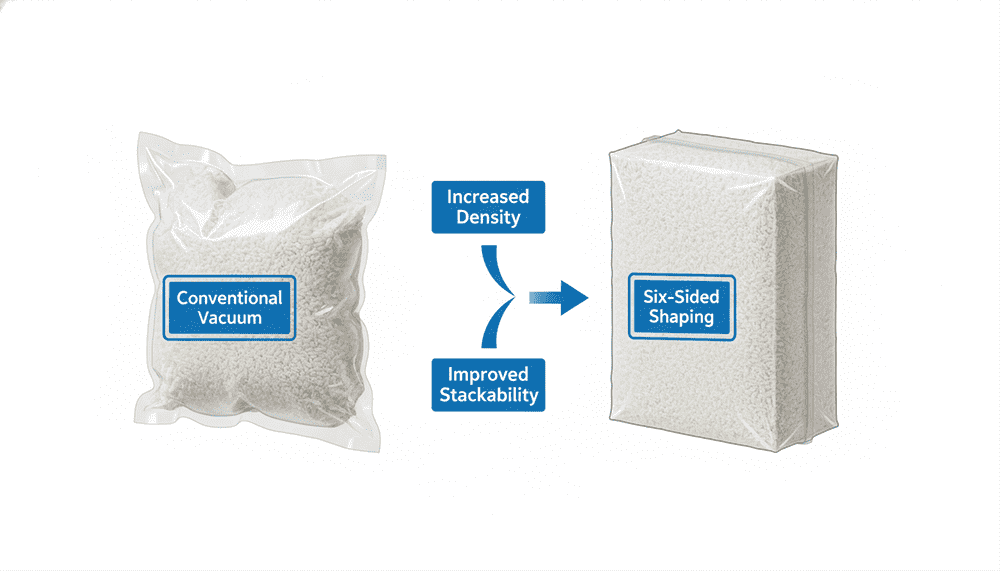

Standard vacuum packaging technology serves a singular primary function: the removal of atmosphere to inhibit spoilage. However, a more advanced iteration of this technology, the six-sided shaping vacuum packaging machine, performs a secondary, equally critical function: it redefines the product's geometry into a stable, cuboid form. This analysis delves into the technical principles of a brick shape packaging machine and explains why it represents a significant leap forward from a conventional food vacuum sealer machine in terms of efficiency, protection, and logistical performance.

A conventional food vacuum sealer machine applies pressure primarily during the atmospheric evacuation. A brick shape packaging machine employs a fundamentally different mechanical process. It utilizes an integrated molding chamber that applies controlled, uniform pressure from six orthogonal directions onto the package *while* the vacuum is being drawn. This multi-axis compaction forces the product into a dense, stable form. Any expert from a packaging machine factory will attest that this is a more complex and effective method of shaping than simple vacuum pressure alone. This technology is a core component of our most advanced automatic packaging systems.

The resulting package from a brick shape packaging machine is a geometrically perfect cuboid. This form factor dramatically improves palletizing density, reducing void space and increasing the amount of product that can be stored or shipped in a given volume. This logistical efficiency is a key reason for integrating a shaping vacuum packaging machine into automated packaging systems. Furthermore, the tightly compacted form provides superior protection against physical shocks compared to a loose bag from a standard food vacuum sealer machine.

Integration into Automatic Packaging Systems

The uniform output of a shaping vacuum packaging machine makes it ideal for integration with downstream automation, such as robotic case packers and palletizers. A reliable brick shape packaging machine is a key enabler for fully autonomous automatic packaging systems. Our packaging machine factory designs these machines with this system-level thinking in mind.

Explore Shaping TechnologyConclusion: A Superior Form Factor for Modern Logistics

The six-sided shaping vacuum packaging machine is more than an evolution of a food vacuum sealer machine; it is a strategic tool for optimizing the entire supply chain. As a leading packaging machine factory, we recognize the immense value this technology provides. A quality brick shape packaging machine is at the core of our most efficient automatic packaging systems.

Consult with Our System Engineers

Let's discuss how the logistical benefits of a brick shape packaging machine can impact your bottom line. We can provide a detailed analysis and configure the right automatic packaging systems for you.

Connect with an Engineer Visit Jialong Technology